Ball Valves: An Overview and Practical Guide

Ball valves are among the most popular types of valves utilized in a variety of industries today, and for a good reason. Their simple operation, combined with durability, gives them a distinct advantage in various applications.

This article is aimed at providing you an all-encompassing insight into ball valves, their operation, applications, maintenance, and some common concerns. We will be sourcing data and information from credible sources. By the end of this article, you’ll have a comprehensive understanding of ball valves.

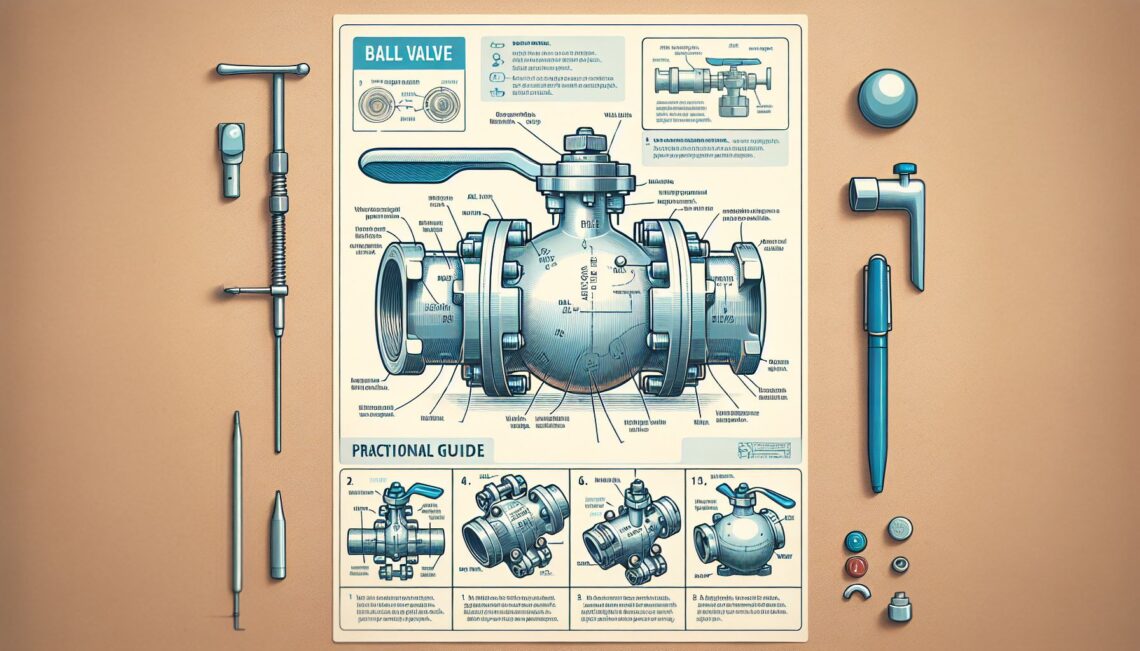

Introduction to Ball Valves

Ball valves are a type of quarter-turn valve which use a hollow, pivoting ball to control flow through it. It’s open when the ball’s hole is in line with the flow and closed when it is pivoted 90 degrees by the valve handle. The handle lies flat in alignment with the flow when open and is perpendicular when closed, making visual confirmation of the valve’s status easy[^1^].

Operation of Ball Valves

Ball valves are easy to use and require no special tools or expertise. Turning the handle quarter-turn (90 degrees) makes it open or closed. When the handle aligns with the pipe, the valve is in the open state, allowing the fluid to flow through. However, when the handle is positioned perpendicular to the pipe, the valve is in the closed state, thus stopping the fluid flow[^2^].

Applications of Ball Valves

Ball valves are widely used in multiple industries, including oil and gas, power generation, marine, mining, and chemical processes. This is primarily due to the valve’s ability to maintain and regulate high pressure, high volume, and high-temperature flow. Ball valves are also ideal for applications requiring secure and leak-proof service[^3^].

Maintenance and Common Concerns

Periodical check and proper maintenance are essential for optimal functionality of ball valves. This involves routine observation for leaks, periodic cleaning, and regular exercise of the valve.

One common concern with ball valves is the potential degradation of the valve seats (due to the friction generated by the ball’s turning), especially if the valve stays open or closed for long periods without change. Regular use can prevent such challenges[^3^].

This happens as the seal is usually created by the pressure of the ball onto the seat, thus any inactivity forms potential leaks.

Conclusion

Ball valves are an essential part of numerous industries due to their versatility, reliability, and efficiency. Proper maintenance and use will ensure their longevity and excellent functionality, thereby providing excellent value and performance.

The life of a ball valve is principally dependent on the application’s compatibility, installation condition, and maintenance strategy. Thus, adequate knowledge about these factors is crucial in making an informed choice for the right type of ball valve for your application.

[^1^]: “Types of Valves.” Valve Manufacturers Association

[^2^]: “How does a Ball Valve work?” Kp-Lok USA

[^3^]: “The Importance of Properly Checking and Maintaining Your Ball Valves.” Northeast Controls