Gate Valves – A Comprehensive Guide

Gate valves, also referred to as sluice valves, are primarily designed to establish a secure shut-off during fluid flow through a pipeline. Leveraging a gate or wedge-shaped disk within the valve body, these devices can control, limit, or terminate the flow. This article pries open a comprehensive guide to the understanding, application, and maintenance of gate valves.

Fundamentals of Gate Valves

Gate valves got their name from their unique construct that implements a “gate” to properly control fluid flow. Unlike other valve types that may throttle the medium flow, gate valves work at their best when fully opened or completely closed. Due to this specific function, they are either utilized to shut off flow (creating a barrier) or permit maximum fluid flow.1^([1])

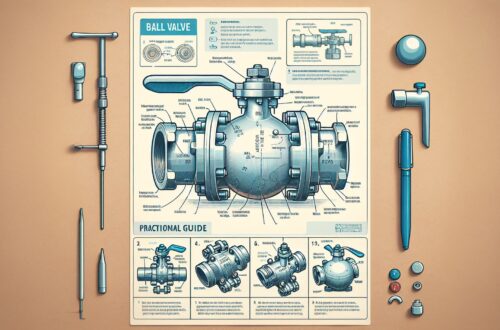

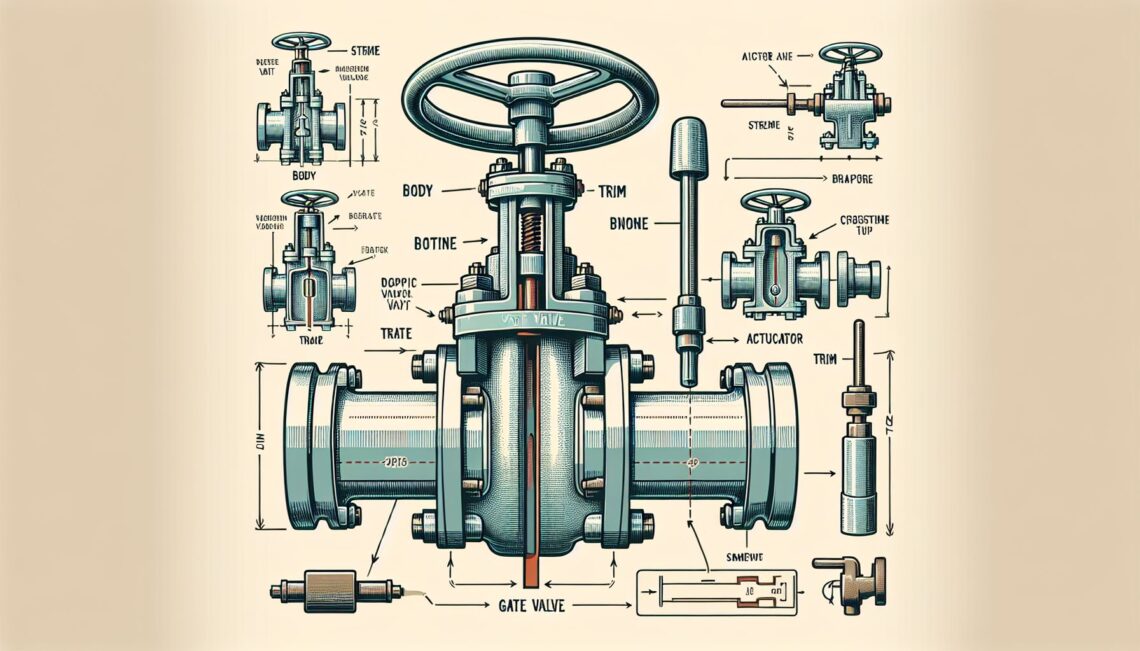

Construction of Gate Valve

The construct of a gate valve generally embeds a valve body, bonnet, seat rings, stem, disk, and handwheel. The disk or gate can be of a solid type, flexible, or split. The solid type is the simplest one providing strength and durability. The flexible variant has around two pieces connected by a mechanism allowing flexibility. The split disk type separates the flow into two, offering better seating arrangement.3^([2])

Applications of Gate Valves

Gate valves are extensively used in various sectors due to their versatility and dependability. A gate valve’s diverse application spread includes industrial settings, chemical processing plants, and power plants, to name a few.

In the oil and gas industry, they are typically used due to their capability to cut through the liquids, allowing uninterrupted fluid flow. Power plants use them during assembly, testing, and boiler firing. In the marine sector, gate valves offer effective control for onboard ships’ fuel systems.

Gate Valve Materials

The selection of material for gate valves is a crucial aspect based on the application. In the industrial sector, forged steel and cast iron gate valves are commonly used. In aggressive environments with highly corrosive or high-temperature applications, alloy materials, stainless steel or bronze valves, may be chosen. The sealing surfaces are generally made out of brass, bronze, or stainless steel.5^([3])

Gate Valve Maintenance and Repair

Periodically checking the valves and keeping them lubricated is vital to prolong their operational life. However, if a gate valve fails, it is advisable to consider the replacement instead of repair.

Valve repair generally involves replacing the damaged components followed by retesting and resetting the valve to its original specs. The choice between replacement and repair may consider various aspects, such as the valve type, availabilities, location, shutdown possibilities, and budgeting.

On the maintenance side, a regular servicing interval is advised to check for any leaks, clean up the valve body, verify the valve packing, and assess the overall valve health.

Conclusion

In summary, gate valves are an important type of valve that is versatile and can be used in a range of applications from industrial to marine uses. The selection of the materials in a gate valve plays a crucial role, and routine maintenance and regular repair of these valves can significantly increase their life span.

Whether it’s understanding the right valve type for your application or deciding the precise operational procedures, choosing gate valves can be a strategic decision providing numerous benefits. With this information, you will be better equipped to make informed decisions about your needs for gate valves.

References

- Valtorc International. (2019). “How Do Gate Valves Work?” Retrieved from valtorc.com

- Kitz Corporation. (n.d.). “Components of a typical Gate Valve.” Retrieved from kitz.com

- Zetco Valves. (2020). “Selection of Material for Gate Valves.” Retrieved from zetco.com