Valve Maintenance – A Comprehensive Guide

Valve maintenance is an often overlooked but undeniably critical aspect of industrial operations. When executed properly, regular maintenance can extend the lifespan of your valves and enhance their performance, saving you significant time and resources down the line. This article aims to deliver comprehensive insights about valve maintenance that will empower you to enhance your operational efficiency. While this task can appear daunting, the right know-how can make it less complicated.

Importance of Valve Maintenance

Preventive maintenance for valves should be a central part of any company’s planning process. This initiative not only enhances performance but also maintains safety and reduces downtime. Let’s dive deeper to understand why comprehensive valve maintenance should not be neglected.

-

Enhanced Performance and Life Span: Regular maintenance extends the life span of your valves and helps avoid unnecessary replacements. It also improves the overall efficiency of your system.

-

Safety: Comprehensive maintenance aids to ward off potential leaks and other failures that can put your plant and workers at risk. Always remember that valves are critical safety elements.

-

Reduced Downtime: Regular valve maintenance preemptively identifies potential failures before they become problematic, reducing downtime and maintaining productivity.

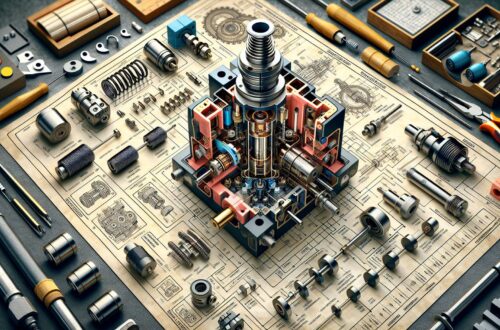

Key Steps for Effective Valve Maintenance

Every organization’s approach may vary because each system is unique and faces different challenges. Nonetheless, some key steps are universally applicable:

-

Regular Inspections:

Carry out inspections at planned intervals to check the valve condition. Search for any signs of damage, leakage, or corrosion. A complete visual check is the first line of defense against any defects that could become bigger problems. -

Cleaning:

Valves should be thoroughly cleaned on a regular schedule. Dust and other debris can damage the interior of the valve, affecting its function and potentially causing blockages or failures. -

Lubrication:

Proper lubrication is an essential aspect of valve maintenance. It minimizes friction, reduces wear, and prevents valve seizure. -

Replacement of worn-out parts:

Any worn-out or damaged parts should be replaced immediately. This initiative keeps the valve in good operating condition and extends their lifespan. -

Documenting the procedures:

Record all your maintenance procedures and findings. Proper documentation aids in troubleshooting any future issues and facilitates scheduled maintenance tasks.

One suggestion is to develop a preventive maintenance plan that aligns with your operations.

Valve Maintenance Common Challenges and Solutions

Valve maintenance can have its set of challenges. Recognizing these issues and knowing how to mitigate them is key. Here’s how to address a couple of them:

Challenge 1: Limited resource availability.

Solution: Innovate. Use predictive maintenance technologies to enhance the efficiency of your processes.

Challenge 2: High costs.

Solution: Practice preventive maintenance. Regular checks and servicing can save you from incurring major repairs or replacements costs down the line.

In conclusion, valve maintenance is a critical task that shouldn’t be overlooked. It calls for systematic planning and diligent execution. Though it may demand a significant investment of time and resources initially, the long-term paybacks are enormous. An investment made towards valve maintenance today is a strategic move for safer, more efficient and more profitable operations tomorrow.

References