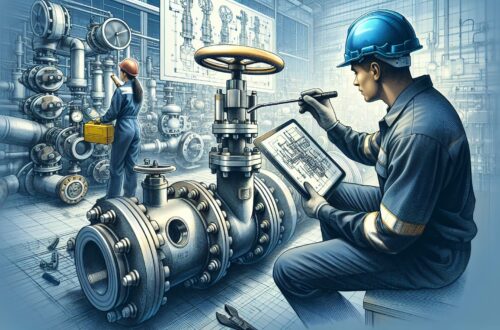

Valve Maintenance

In the world of industrial processes, valves play a critical role to ensure that systems operate efficiently and safely. These versatile devices control the flow and pressure of liquids, gases, and slurries within a system, making it crucial for workers to understand the right way to maintain these valves to prolong their life and ensure optimal performance. Ensuring proper valve maintenance can also mitigate the risk of sudden breakdowns, costly repairs, and system downtime.

The Importance of Valve Maintenance

A valve left without proper maintenance can cause inefficiency in the system, and in the worst-case scenarios, result in potentially hazardous incidents. A poorly maintained valve can lead to leakages, faulty operation, and even pose a risk of catastrophic failure. Therefore, it is essential to maintain a regular valve maintenance schedule to maximize efficiency and safety.

Regular Inspection

First and foremost, a periodic inspection is necessary as part of valve maintenance and should never be neglected. By visually inspecting, one can identify any visible wear and tear, leaks, or other irregularities that may indicate potential problems.

Cleaning

Cleaning is an essential step in valve maintenance. Dirty or clogged valves can significantly decrease efficiency and cause the valves to malfunction. Therefore, it’s crucial to clean the valves regularly to remove any built-up residue or contaminants.

Regular Testing

Regular testing of the valves can also help identify any abnormalities in their performance early on. For example, pressure testing can validate a valve’s capacity to withstand its rated pressure without causing any leakages.

Lubrication

Regular lubrication of the valves is important to prevent friction between moving parts and enhance durability. It is important to use a suitable lubricant for this purpose to ensure effective lubrication.[^1^]

The Frequency of Valve Maintenance

Determining how often to perform maintenance on your valves can depend on several factors, including the type of valve, the nature of the fluid being controlled, and the conditions under which the valve operates. High-pressure systems, corrosive substances, or high-temperature environments may necessitate more frequent maintenance checks.

Professional Valve Maintenance

Although routine inspections and simple maintenance tasks can be performed by regular staff, it’s often advisable to have professional technicians perform more detailed maintenance.[^2^]

Usually, this will involve detailed inspections, thorough cleaning, and testing. Professional technicians will have the knowledge and tools to accurately assess the condition of the valves and perform any necessary repairs or replacements.

Conclusion

Valve maintenance is an essential aspect of managing industrial systems. Regular inspection, cleaning, lubrication, and testing are all key components of maintaining valve efficiency, performance, and safety. By implementing a regular maintenance schedule and employing professionals for more complex tasks, industries can ensure their valves remain in top condition, thereby increasing system efficiency, reducing the risk of accidents, and extending the lifespan of their valves.[^3^]

[^1^]: Valve Maintenance: To Extend the Valve’s LifeValve Magazine

[^2^]: Routine Maintenance for Different Types of ValvesSouthwest Seal & Supply

[^3^]: A Practical Guide to Valve MaintenanceProcess Industry Forum