Valve Maintenance: A Comprehensive Guide

Whether you’re an industry professional, a hobbyist, or just a homeowner looking to understand more about the mechanisms that surround you daily, knowing your way around valve maintenance can be a valuable skill.

Valves play a critical role in numerous applications, from controlling the flow of water in our homes to managing the operations in large-scale industrial tasks. Despite their prevalence and importance, their maintenance often gets overlooked. Regular valve maintenance not only ensures efficacy and longevity but also averts potential hazards. With that in mind, this article will leap into the world of valve maintenance, guiding you through in-depth knowledge and reliable strategies to maintain various types of valves.

Understanding Valve Maintenance

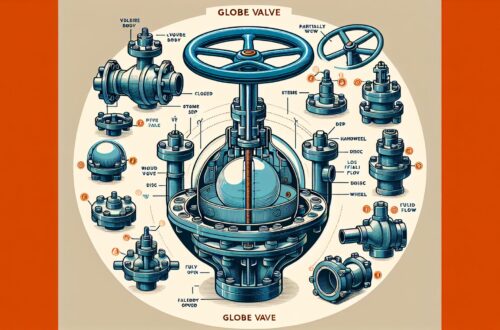

Valves are ubiquitous, and they come in a variety of types based upon their design and function. The most common among them are ball valves, butterfly valves, check valves, gate valves, globe valves, solenoid valves, etc. Each of these has a unique operation mechanism and, thus, requires individual care and maintenance regime[^1^].

Why is Valve Maintenance Significant?

Regular valve maintenance is vital for several reasons:

- Longevity: Proper care and routine maintenance significantly extend the lifespan of valves, saving replacement costs.

- Efficiency: Regularly maintained valves operate more smoothly and efficiently, leading to better performance and less energy consumption.

- Safety: Valve malfunctions can lead to safety hazards, especially in industrial settings. Regular maintenance helps prevent such accidents.

Key Steps in Valve Maintenance

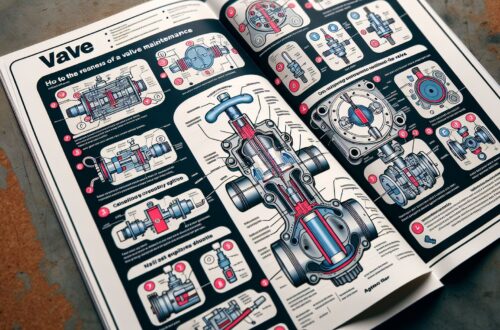

The following are the elementary steps of valve maintenance:

-

Inspection: Regular inspection is the first step towards efficient valve maintenance. It helps in identifying corrosion, leakage, or other wear and tear signs.

-

Cleaning: Over time, dust, grime, and other foreign materials can accumulate on the valves, leading to reduced performance. Regular cleaning with appropriate cleaning agents is necessary to maintain the longevity and functionality of the valves[^2^].

-

Lubrication: Different types of valves may need lubrication to keep the moving parts functioning smoothly. Always use the recommended type and amount of lubricant.

-

Functionality Check: Following inspection and cleaning, it’s essential to check the functionality of the valve by manually operating it to ensure its correct and smooth operation.

-

Replacement of Damaged Parts: If any parts are damaged and beyond repair during the inspection, they should be promptly replaced. Regular replacement of seals and gaskets is good practice to prevent leakages[^3^].

Conclusion

Regular valve maintenance is an integral part of maintaining a safe and efficient operating environment, whether in a domestic context or within industry-scale operations. It’s essential to follow recommended maintenance practices and guidelines to ensure that your valves are always in optimal condition. Regular inspection, cleaning, and lubrication, along with timely replacement of damaged parts, are the trademarks of effective valve maintenance.

Remember, prevention is better than cure, so don’t wait for your valves to give you clear signs of deterioration. Implementing regular valve maintenance checks can potentially save you from unexpected breakdowns and significantly extend the life span of your valves.

[^1^]: Valve Types and Features. (2020). Hitachi. [https://www.hitachi.com/products/infrastructure/support/valve/guide/valve02.html]

[^2^]: Shoup, D. (2013). Common Valve Types. Valve Magazine. [https://www.valvemagazine.com/home/features/5848-common-valve-types.html]

[^3^]: Valve Maintenance Tips. (2019). Valve World Americas. [https://www.valveworldamericas.com/news64918.html]