Valve Maintenance: Essential Steps and Practices

Valve maintenance may not sound like the most exciting aspect of running a system or an operation, but it’s requisite to know that they are incredibly vital. Valves ensure the functioning, safety, and efficiency of a wide range of industrial applications, ranging from domestic water systems to major manufacturing and petrochemical processes.

So, let’s delve into the intriguing world of valve maintenance. Let’s cover the basics, why it’s necessary, preventive routine checks, extensive repairs, and the actual maintenance process.

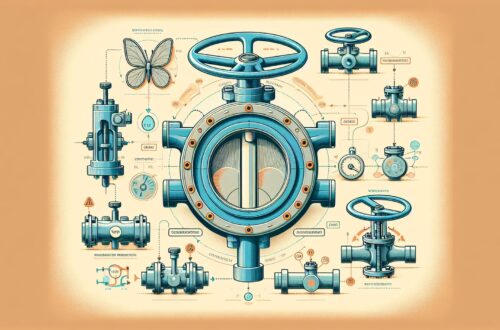

What Is Valve Maintenance?

Valve maintenance encompasses a set of procedures aimed at optimizing the functionality of valves in a system. It includes routine inspections, cleaning, replacement of faulty components, lubrication of moving parts, adjustments, testing, and full-scale repairs conducted periodically or as and when required.

Valve maintenance is carried out in three key stages. This starts with an initial inspection. This helps identify any signs of wear or impending failure. It then moves into the repair or replacement stage. Finally, it ends with regular testing to ensure that the valve is functioning at optimal levels.

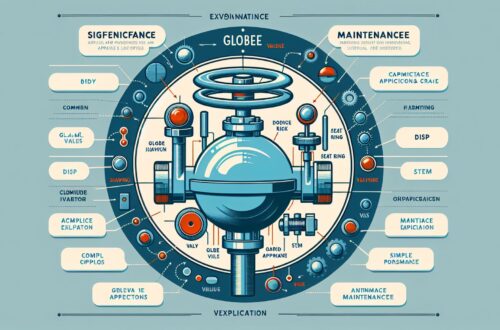

Importance of Valve Maintenance

An improperly maintained or faulty valve can downgrade the integrity of a whole system. For instance, a faltered safety valve in a boiler can lead to a dangerous build-up of pressure, causing significant damages on explosion.

Routine valve maintenance provides benefits, such as:

- Reducing likely system downtime.

- Enhancing operational safety.

- Prolonging the lifespan of the valves and related equipment.

- Preventing significant repairs or replacements that could incur hefty costs.

Preventive Maintenance Checks

A crucial aspect of valve maintenance is implementing regular preventive checks. These checks help in spotting imminent failures before posing serious threats. General recommendations include:

- Visual inspection for leaks, physical damages, or signs of wear.

- Verification of valve movement and alignment.

- Checking and replacing gaskets and bolts as necessary.

- Lubrication of valve stems and operators.

- Testing of valve operations and responses.

Repair and Replacement

Maintaining valves may also involve repair or replacement procedures for parts that may fail over time. This may include:

- Replacing worn-out stem seals, body gasket, seat rings, or packing gland.

- Repairing the valve body or bonnet surfaces.

- Lubricating, refitting, or replacing valve stems and actuator components.

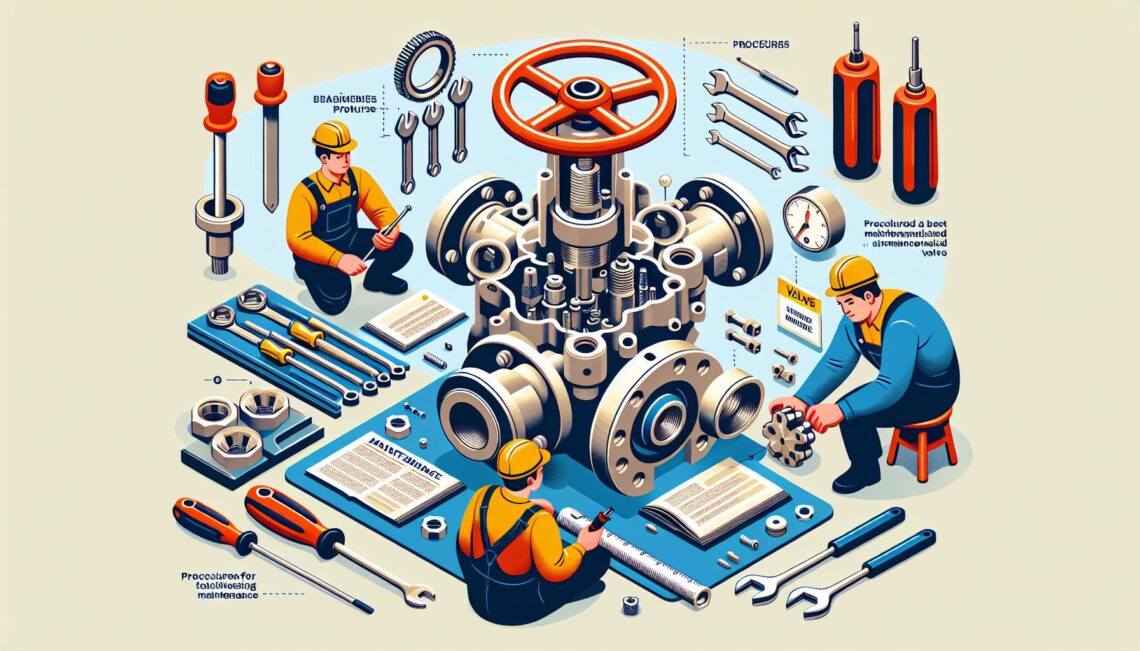

The Valve Maintenance Procedure

Here’s what the standard valve maintenance procedure might look like:

-

Shutting It Down: The operating system is shut down, and the valve is isolated.

-

Dismantling: Necessary components, depending on the valve type, are dismantled. This usually involves the removal of the bonnet, trim (stem, plug, disc), gasket, seal, or packing.

-

Cleaning: The removed parts and valve body are cleaned thoroughly.

-

Inspection: The cleaned components are inspected for signs of wear or damages.

-

Repair or Replacement: Necessary repairs are made, or damaged components are replaced.

-

Reassemble and Testing: The valve is reassembled, and operational tests are performed for leaks or other functional issues.

-

Readjustments: Any necessary adjustments are made after reassembly.

Regular valve maintenance may seem a daunting task at first, but it’s surely worth the investment of resources. It fosters a high operational safety level while preventing costly pitfalls of major system malfunctions over time.

Sources

- Valve Magazine (www.valvemagazine.com)

- Fluid Handling Pro (www.fluidhandlingpro.com)

- Valve World (www.valve-world.net)