Valve Maintenance: A Comprehensive Guide

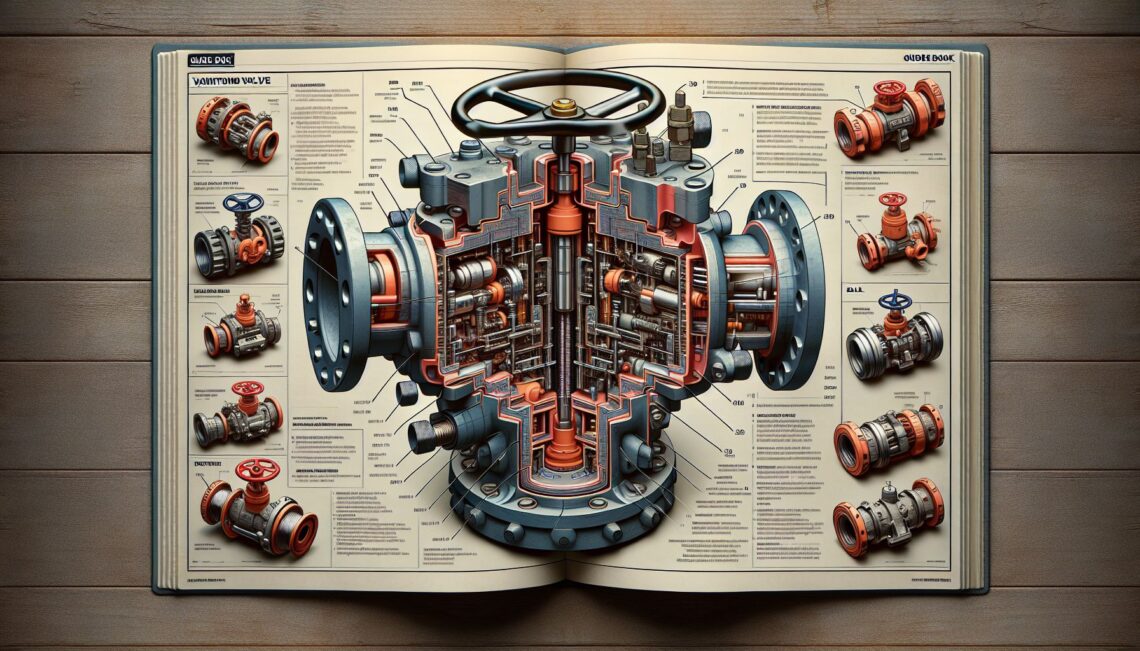

Valve maintenance plays a crucial role in ensuring the optimal operation of various system components and the process as a whole. This direction is beyond just understanding how valves function, it also involves creating a proper maintenance strategy and a keen eye for recognizing problems.

What is Valve Maintenance?

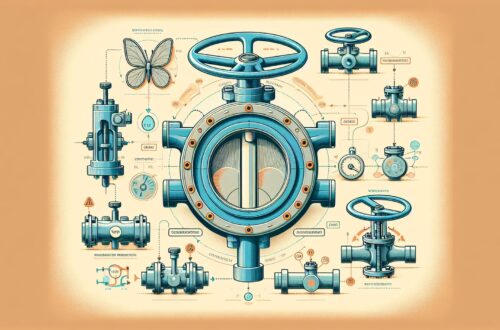

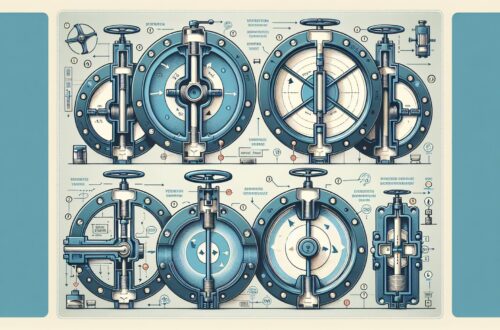

No industrial plant, regardless of its type, can operate efficiently without utilizing different types of valves. These valves control flow rates, hold and relieve pressure, and stop or start the flow of fluids. However, like any mechanical component, they are subject to wear and tear and require routine maintenance. Valve maintenance ensures their smooth operation, prevents system failure, reduces downtime, and increases their lifespan (source).

Importance of Valve Maintenance

Regular valve maintenance ensures all components continue to function as originally intended. A poorly maintained valve can compromise your system performance, leading to leaks, failures, inefficiencies, and safety issues. When properly maintained, a valve’s lifespan can be significantly extended, saving time and money in the long run (source).

Key Elements of Valve Maintenance

Implementing an effective valve maintenance program can be broken down into three key steps:

-

Inspection: A routine inspection can detect any abnormal noises, leaks, temperature changes, or malfunctions which may indicate that a valve requires attention. It also involves checking the overall system pressure and flow rates.

-

Cleaning: Dust, dirt, and rust shorten the lifespan of valves. Regular cleaning can ensure a valve functions effectively and enhances its life expectancy.

-

Lubrication: Lubrication is vital for the optimal operation of valves. It reduces friction, heat, and wear, while also providing a seal to prevent leaks.

Common Valve Maintenance Challenges

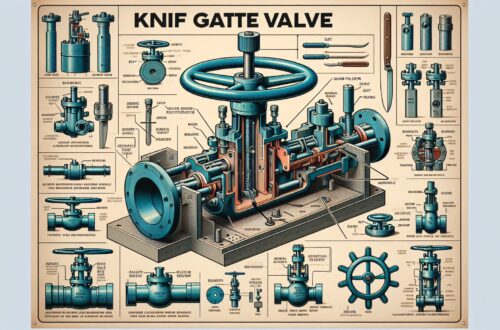

While maintaining valves does not require an engineering degree, it can throw up challenges that are not always easy to overcome. For example, certain valves may be located in hard-to-reach areas of your plant or pipeline. In other instances, the valve might have intricate designs that call for special tools or knowledge to service (source).

When to Replace your Valves

Even with proper maintenance, all valves will eventually need replacing. It’s important to be mindful of factors that could indicate a replacement may be needed. These could include poor system performance, excessive noise or vibrations, leakages, or unusually high energy consumption.

Remember, while performing repairs or replacements, always adhere to valve standard practices and ensure correct valve sizing, selection, and installation.

Conclusion

Proper valve maintenance is crucial for operational efficiency and the longevity of your valves. Although each valve may have different maintenance requirements, regular inspections, cleanings, and lubrication remain the universal constants. By adhering to a strategic valve maintenance program, you can extend the lifespan of your valves, reduce downtime, and, ultimately, save costs.

Sources: