Valve Selection

Valve selection is an essential aspect of most industrial processes. From the petrochemical industry to food and beverage production, valves play a critical role in controlling flow, pressure, and temperature. However, with a plethora of valve types available, choosing the right valve for a specific application can be quite daunting. This article will help you understand the factors that you need to consider while selecting a valve for your needs.

What is a Valve?

In simple terms, a valve is a mechanical device that controls the flow and pressure of fluids like gases, liquid, and fluidized solids. Valves can be found in various applications, including home appliances, industrial process systems, and even within our bodies!

Factors to Consider in Valve Selection

There are several key factors to consider when selecting a valve for your application:

1. Fluid Characteristics

Before you select a valve, you need to consider the characteristics of the fluid that will pass through the valve. This includes fluid density, viscosity, temperature, and the presence of solid particles.

2. Flow Control Needs

Depending on the required flow control in your process, you would need to select a different valve. For example, if you need an ON/OFF control, a ball valve or a butterfly valve could be an option. For throttling control, you might consider a globe valve.

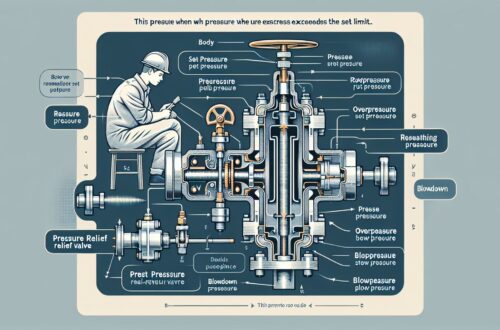

3. Operating Pressure & Temperature

Each valve is designed to operate under a specific pressure and temperature. It is essential to select a valve that can handle the pressure and temperature in your application.

4. Material Compatibility

The material of the valve should be compatible with the fluid. Incompatible materials could lead to corrosion and decrease the life-span of the valve.

5. Cost

Although cost should not be the primary factor in valve selection, it must be considered. The cost includes not just the purchase price, but the installation, operation, and maintenance costs as well.

Valve Types

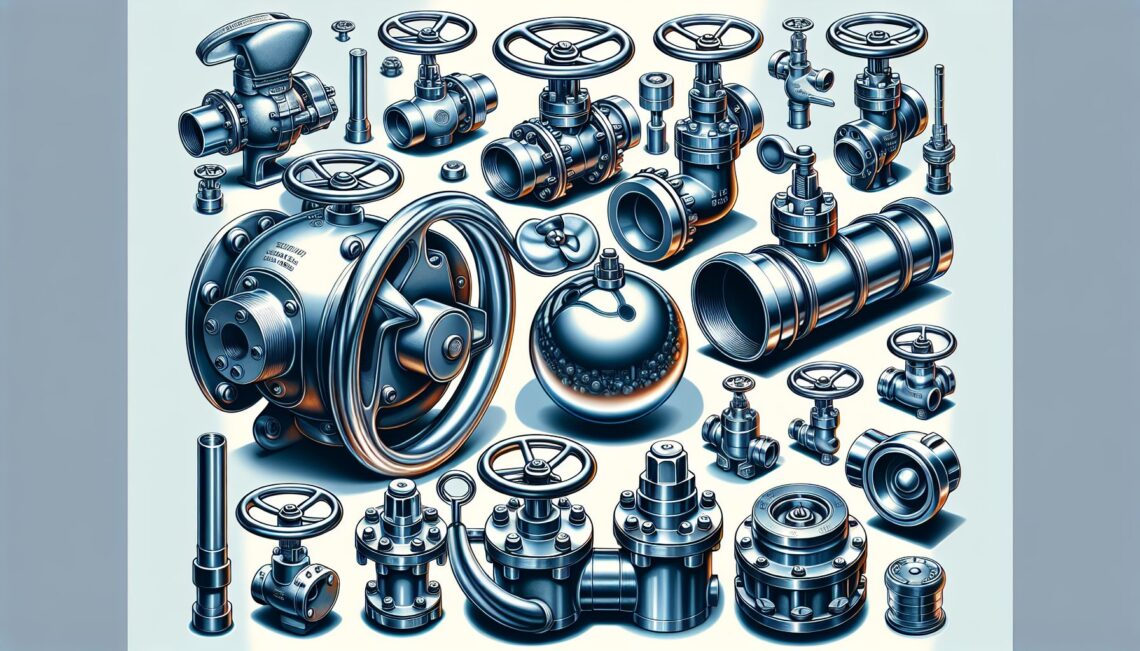

Each of these factors can influence the type of valve you should choose. Here’s a brief overview of some common valve types:

Ball Valves

Ball valves are best for applications that require fast and frequent operation. They provide a tight shut-off and control flow well even under high pressure.

Butterfly Valves

Butterfly valves are ideal for controlling large flow volumes. They open and close quickly and require minimal space.

Check Valves

Check valves are designed to allow flow in one direction only and to prevent backflow. They are commonly used in pumping applications.

Gate Valves

Gate valves are used where a straight-line flow of fluid with minimum restriction is desired. They are often used as shut-off valves in pipeline systems.

Globe Valves

Globe valves are used for applications where flow control is necessary, particularly when throttling is required. They are also efficient for shutoff purposes.

Diaphragm Valves

Diaphragm valves are well-suited for handling corrosive fluids, gases, and slurries. They are also used in sterile applications like pharmaceutical or food and beverage production.

Conclusion

While it might seem overwhelming, selecting the right valve is essential for the success of your process. With a clear understanding of your application’s requirements and the different options available, you can make a well-informed decision that will ensure the efficiency and safety of your operations.

Sources:

- “Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow Application” by Peter Smith, R. W. Zappe

- “Industrial Valves: How to Select the Right Valve for Your Application” by IDC Technologies

- “Valve Selection: An Engineer’s Guide to Specifying the Right Valve” by PIP Process Industry Practices