Ball Valves

Ball valves are outstanding devices known for their ability to provide tight shut-off and control over complex systems. They have unique features and characteristics that make them superior in many applications, mainly in systems involving gases, corrosive substances, and high temperature conditions. This article will delve into the fascinating world of ball valves, covering their structure, function, types, applications, and benefits. We’ll also touch on the vital aspects of ball valve maintenance and repair.

What are Ball Valves?

A ball valve is a type of quarter-turn rotary valve that uses a hollow, perforated, and pivoting ball to control flow. It’s open when the holes are in line with the flow and closed when it’s pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status[[^1^]][1].

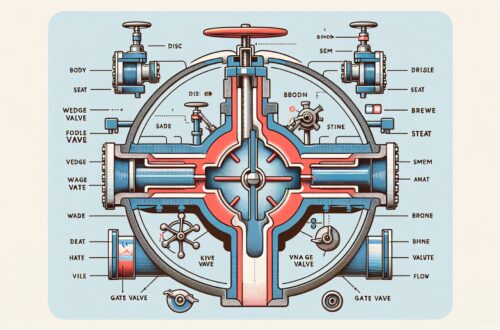

Structure of Ball Valves

The primary component of a ball valve is a spherical disc, the part of the ball valve that controls the flow through it. Other key parts include:

- Body: The body encloses the internal parts of the valve.

- Stem: Connects the ball and the actuator (lever, gear, actuator) and is responsible for the proper positioning of the disc.

- Seats: Provide the necessary sealing between the body and the ball.

- Seals / Packing: Ensures the stem region is leak-proof, preventing any potential external leaks[[^2^]][2].

Types of Ball Valves

Ball valves come in various types depending on the bore of the ball mechanism itself; these include:

- Full Port Ball Valve: They have an over-sized ball so the hole in the ball is the same size as the pipe resulting in lower friction loss.

- Reduced Port Ball Valve: They use a smaller ball, which is smaller than the pipe, leading to a smaller flow path.

- V-port Ball Valve: The ball has a ‘v’ shaped hole, allowing for more flow control as the valve opens and closes.

- Cavity Filler Ball Valve: These valves have a single piece design that makes the assembly of the valve easier[[^3^]][3].

Ball Valve Materials

Common materials used for ball valves include:

- Brass: This is suitable for some drinking water applications

- Bronze: Commonly used for seawater service

- Chrome: Perfect for high temperature and pressure applications

- Stainless Steel: Has broad applications due to its corrosion resistance capability.

Ball Valve Applications

Due to their ease of control and versatility, ball valves are found in a variety of industries. They are commonly used in manufacturing sectors, including oil and gas, food and beverage, pharmaceuticals, and more. In residential areas, they are often used for water supply and irrigation purposes[[^2^]][2].

Benefits of Ball Valves

Ball valves provide exceptional shutdown capabilities. They are efficient in maintaining and regulating high volume, high pressure, and high-temperature flow. Another fantastic feature is their easy operation; Ball valves can open and close swiftly. Their strong and durable structure gives the promise of a long service life.

Maintenance and Repair

Proper maintenance of ball valves increases their lifespan significantly. One can clean the valve routinely to get rid of dirt and dust. Also, it is wise to perform leak tests regularly. In the event of necessary repairs, only replace the damaged part rather than changing the entire valve, as this will save costs[[^1^]][1].

By understanding ball valves inside out, you can make the most of their features for your applications, ensuring efficiency, and cost-effectiveness. As always, the key to optimal performance is proper usage and regular maintenance.