Globe Valves: A Comprehensive Overview

Globe valves are a common but integral part of many industrial systems. Some may view them as simple tools of flow regulation, but for those who grasp their ins and outs, globe valves can be recognized as indispensable components that ascertain system safety and operational efficiency. This extensive article will help you understand globe valves better, from their structure and operation to their applications and maintenance.

What are Globe Valves?

Globe valves, distinguished by their spherical shape, are utilized to regulate fluid flow in a pipeline. They are designed to throttle or stop the flow, making them highly versatile. Often you’ll find them in applications requiring precise flow control and frequent on-off cycles[^1^].

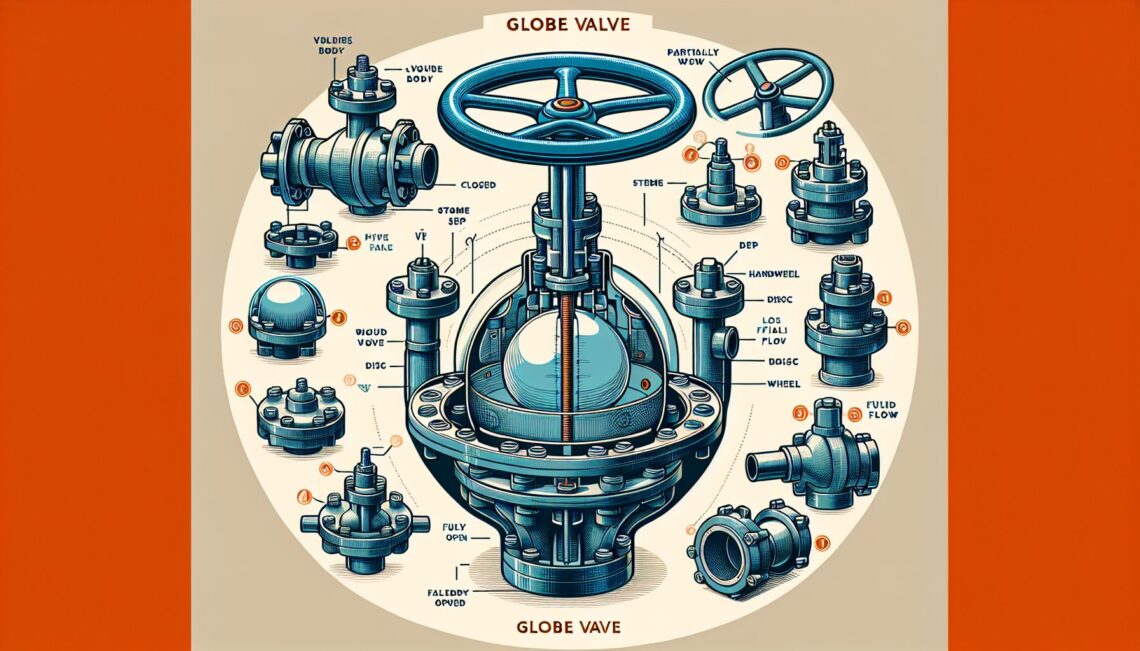

Structure of a Globe Valve

A standard globe valve consists of various components. At its core, it features a movable disk and a stationary ring, termed the “seat”. Fluid flow is controlled by altering the position of the disk relative to the seat. The valve’s stem, connected to the actuation device on top, enables the movement of the disk within the valve body[^2^].

The valve body’s shape is where the name “globe” originates. These bodies can further be classified into three types: T-pattern, angle, and Y-pattern, each having unique flow patterns.

How Globe Valves Work

Workings of a globe valve depend on the disk’s movement. To open the valve, the handle or actuator is turned, lifting the disk and allowing fluid to flow. Conversely, turning the handle in the opposite direction lowers the disk onto the seat, stopping the flow.

The key benefit is the precise flow control – given the disk can be positioned at varying heights from the seat, it allows for a wide range of flow levels.

Applications of Globe Valves

Globe valves are highly versatile and can be found in numerous applications. They shine in situations requiring tight sealing and precise flow control. Frequent usage can be seen in power plants, water and wastewater treatment facilities, and various types of manufacturing plants[^3^].

They’re also commonly used in building applications, such as steam heating systems, where the prevention of backflow is crucial.

Maintenance and Repair of Globe Valves

Maintenance of globe valves typically revolves around ensuring the sealing surfaces (disk and seat) are free from dirt or damage, and the stem movement remains unobstructed. In some cases, the seal can wear out or become damaged, requiring replacement[^3^].

Typically, repairs involve disassembling the valve and manually inspecting and cleaning the components. Wear-resistant or corroded parts are replaced, and the valve is then reassembled and tested.

To Sum Up,

Globe valves, with their characteristic spherical shape and internal makeup, are crucial components for controlling and regulating fluid flow in various systems. Their ability to offer a fine degree of flow control makes them a valuable asset in countless applications. Like any mechanical device, they require regular maintenance and repair to ensure proper operation over time.

[^1^]: GlobalSpec – Globe Valves Information

[^2^]: Engineering ToolBox – Globe Valve

[^3^]: Flowserve – Industrial Maintenance for Globe Valves