Valve Maintenance: Maintaining Optimal Functionality and Efficiency

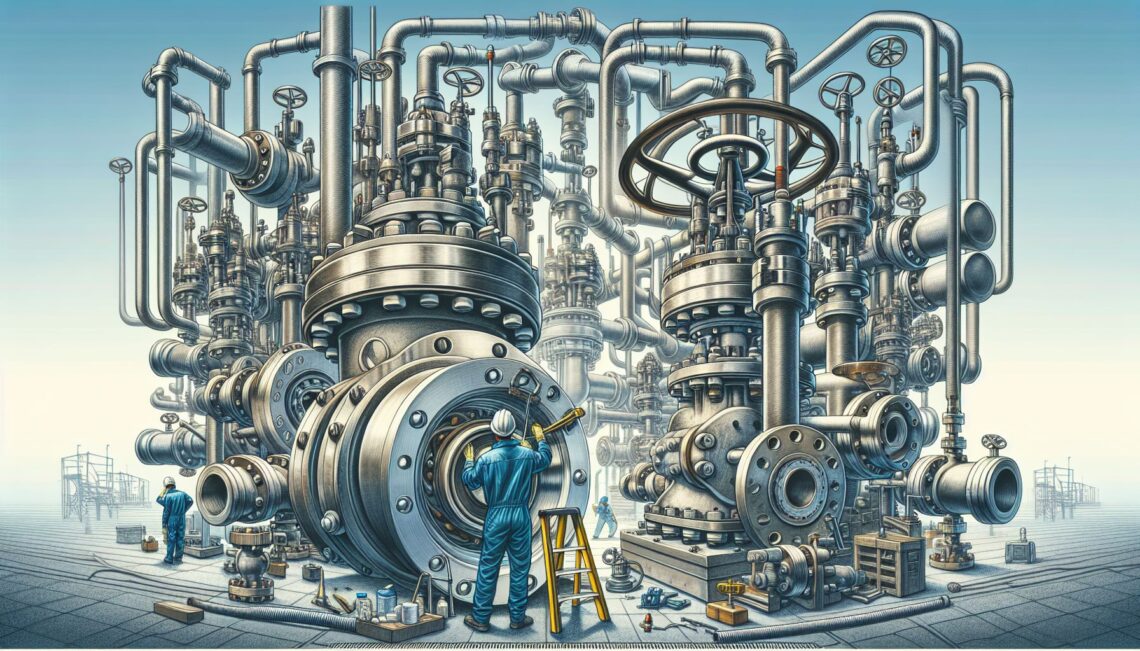

Valves are essential components in numerous industrial applications, including oil and gas, water treatment plants, power generation plants, mining, and many more. They control the flow and pressure of fluids within the system, ensuring efficient and safe operations. However, like any other mechanical equipment, valves are subject to wear and tear, making valve maintenance crucial in maintaining optimal functionality and prolonging their lifespan. This article will be your comprehensive guide to valve maintenance.

Why is Valve Maintenance Important?

Valve maintenance is a vital element of any well-designed maintenance management program. The primary goal of valve maintenance is to prevent failures and breakdowns before they occur. Prolonged use of valves can lead to issues like leaks, blockages, and valve failure, which can significantly affect overall plant operation and safety.

Here are the key benefits of regular valve maintenance:

Preventing premature valve failure: Valves, especially in extreme operating conditions, can experience excessive wear. Regular maintenance can identify any early signs of deterioration, allowing for preventative measures.

Ensuring Safety: Malfunctioning valves can cause safety hazards, especially when dealing with hazardous materials. Regular valve maintenance ensures that valves operate correctly, minimizing the risk of accidents.

Extending Service Life: Regular maintenance can significantly extend the lifespan of a valve. This can be financially beneficial as it potentially eliminates the need for premature replacement.

Maintaining Efficiency: A well-maintained valve performs better, leading to improved efficiency in the overall plant operation.

The Basics of Valve Maintenance

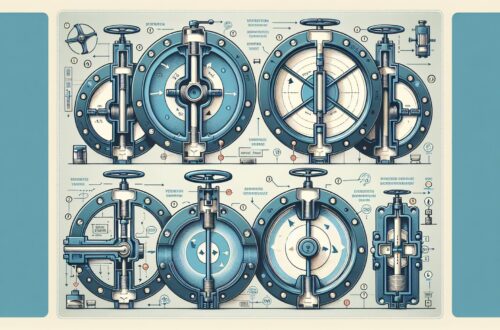

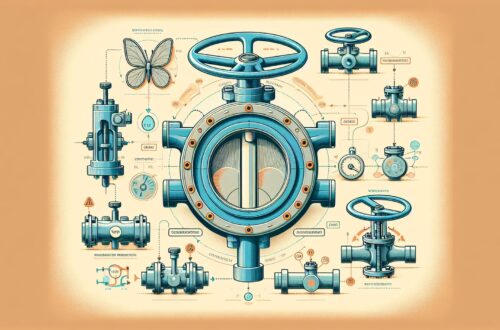

Valve maintenance procedures may vary depending on the valve type, material, size, and its function within a system. However, some general maintenance practices apply to all valves, such as:

Regular Inspection: A regular visual inspection is a basic but essential maintenance practice. Look for any signs of leakage, wear, or damage. Pay particular attention to the valve body, stem, bonnet, packing, and adjacent pipework.

Routine Functionality Testing: Regular testing ensures that valves operate as they should, allowing timely identification of any potential issues.

Cleaning: Depending on the system’s fluid, valves may require regular cleaning to remove any deposits or debris that could affect their performance.

Lubrication: Valves, particularly those with moving parts like gate valves or ball valves, require periodic lubrication to ensure smooth operation.

Sealing and Packing: Regular inspection and maintenance of the sealing and packing materials are vital to prevent leaks and ensure tight sealing.

Advanced Valve Maintenance Practices

Beyond these fundamentals, more specific and technical maintenance activities based on individual valve features should be considered:

Pressure Testing: One of the most common ways to check for leaks or damage in valves is through pressure testing. This involves applying a pressure greater than the valve’s operational pressure to test its integrity.

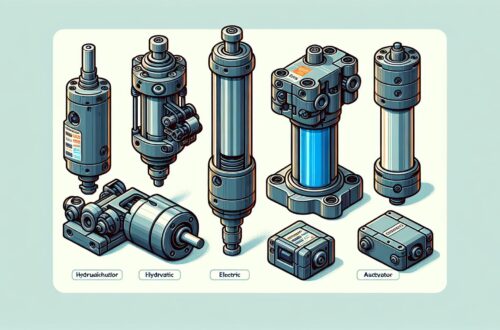

Actuator Testing: Actuators convert energy into valve motion. It is crucial to test actuators regularly to ensure they operate optimally.

Valve Packing Adjustment: If a valve leaks around the stem, a simple fix could be tightening the packing gland. However, over-tightening can cause damage, so adjust cautiously.

Checking Valve Alignment: Misalignment can lead to excessive wear and tear. Conduct regular alignment checks to ensure the valve and pipe axis are parallel.

Replacing Worn Components: Over time seals, gaskets, packing, and other components can wear out. Replacing worn-out parts is a vital part of valve maintenance to ensure optimal functionality.

Professional Valve Maintenance Services

While some basic maintenance tasks can be done in-house, specialized maintenance tasks such as pressure testing, actuator testing, and advanced repairs should be left to professionals to ensure proper handling and safety.

Valve manufacturers often provide maintenance manuals and support. It is vital to follow these guidelines when undertaking any maintenance activity. You may also seek professional services from industrial valve maintenance and repair services providers, who have specialized training and equipment.

Conclusion

Valve maintenance is critical for efficient and safe plant operation. A well-planned and executed valve maintenance regimen can prevent premature valve failure, ensure safety, prolong valve service life, and maintain plant efficiency.

Regular inspections, routine functionality testing, cleaning, lubrication, and sealing and packing checks are fundamental maintenance practices. More advanced practices, such as pressure testing, actuator testing, valve alignment checking, and replacing worn components, require more expertise and resources.

While some maintenance activities can be performed in-house, more specialized tasks are best left to professional service providers. No matter the approach, never underestimate the importance of valve maintenance in ensuring your plant’s overall operational efficiency and safety.

References