Butterfly Valves: A Comprehensive Guide

Valves are essential components in a multitude of industries. They are designed to control and modulate the flow of liquid or gas within a system. There are various types of valves, each with unique features suited to specific applications. One of the most commonly used valves is the butterfly valve. This article presents a comprehensive guide to butterfly valves, covering everything from their structure and working principle to their uses, benefits, and selection criteria.

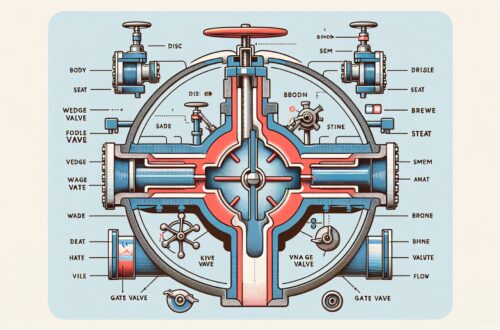

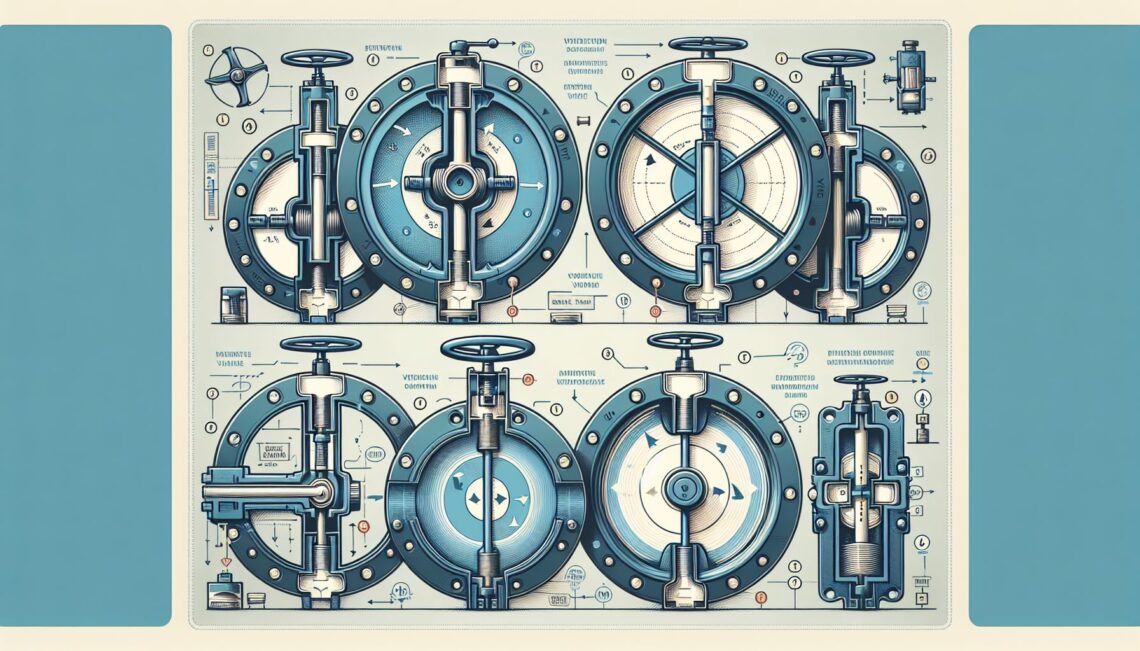

Structure of Butterfly Valves

A butterfly valve consists of a disc mounted on a rotating shaft. When the valve is fully closed, the disc blocks off the passageway. When the valve is fully open, the disc rotates a quarter turn so it’s almost parallel to the direction of fluid flow (1).

Working Principle

The modulating element (the disc) of a butterfly valve operates similarly to a gate or globe valve. As the actuator rotates the disc, it either increases or decreases the flow passage, allowing the operator to control the flow rate within the system (2).

Uses of Butterfly Valves

Butterfly valves are used extensively in various industries, thanks to their reliability, ease of use, and economic value. Some of the popular industries include:

- Water and Wastewater Management: Butterfly valves efficiently manage the flow and pressure of water and wastewater in treatment plants.

- Oil and Gas: In oil and gas industry, these valves are used in pump isolation, and throttling services.

- Chemical Processing: In the chemical industry, butterfly valves control the flow of a large number of fluid products.

- HVAC: Butterfly valves are used in heating, ventilation, and air conditioning systems to control the flow of air and other gases (3).

Benefits of Butterfly Valves

Butterfly valves shine in their simplicity and effectiveness. They are lightweight, easy to assemble and operate, require less maintenance and space, provide perfect shutoff, and are more cost-effective compared to other valve types.

Choosing the Right Butterfly Valve

When choosing a butterfly valve, some factors need to be considered:

- Pressure and Temperature: Understanding the pipeline pressure and fluid temperature is key in selecting the right valve.

- Fluid Density: It’s crucial to know the type and density of the fluid that the valve will be controlling.

- Actuator Type: You need to decide whether a manual, electric, hydraulic, or pneumatic actuator would be most suitable.

- Size of Pipe: The appropriate sized valve should be selected to match the size of the pipe where it will be installed.

Butterfly valves play a critical role in controlling and isolating the flow in systems across a range of industries. They are respected for their durability, simplicity, and cost-effectiveness. However, selecting the right butterfly valve involves understanding the fluid’s characteristics, system requirements, and the valve’s quality. It demands a holistic approach of looking at system specifications, unique application requirements, and industry standards.