Gate Valves: A Comprehensive Guide

When it comes to controlling the flow of liquids, gases, and other miscible substances, valves are a crucial part of any mechanical system. One cannot overlook the importance of gate valves in such setups. This article delves into a comprehensive exploration of all aspects related to gate valves.

What are Gate Valves?

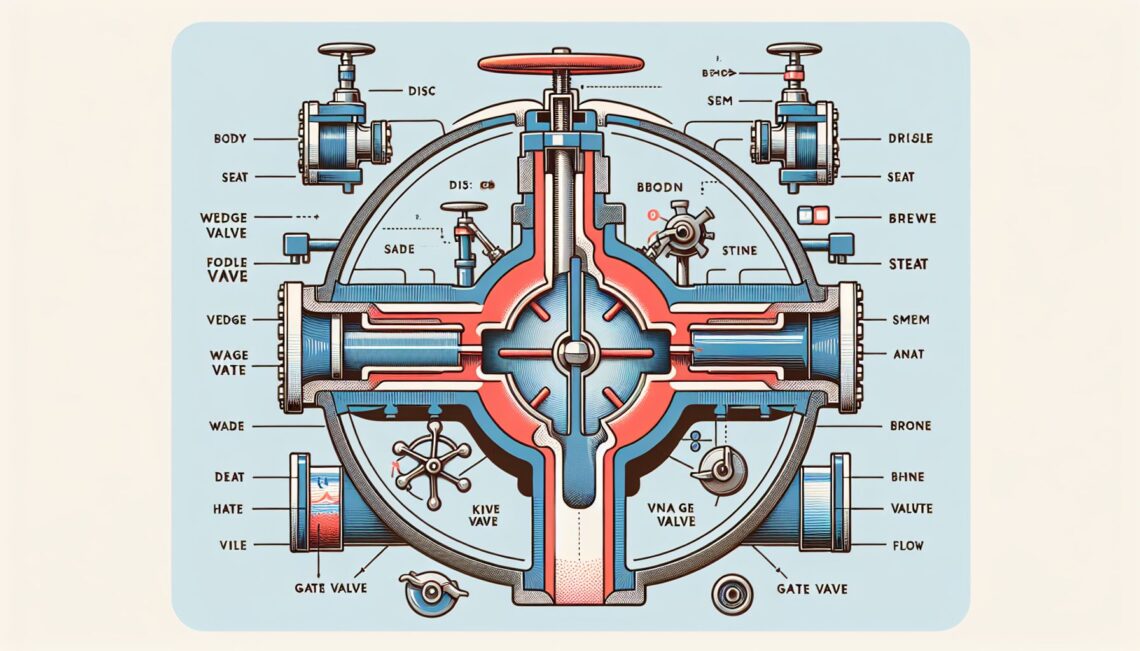

A gate valve, also known as a sluice valve, is a type of valve used primarily to permit or prevent the flow of liquids. It does this by raising or lowering a rectangular or round gate by use of a rotating stem¹. The primary characteristic of gate valves is their ability to cut-off media completely.

Applications of Gate Valves

Gate valves find use across various industries and applications². Some of their most common applications include:

– Underwater applications: Due to their robust nature, gate valves are often used in underwater operations.

– Oil and gas industries: For controlling the flow of different petroleum products, gate valves serve as an efficient tool.

– In building piping systems: For controlling the building’s water supply, gate valves are used.

Gate Valves Vs. Other Valve Types

Each type of valve has its unique features, and gate valves are no different. The comparison below will explore some of these features against other valves types such as ball valves, check valves, and butterfly valves³.

– Gate valves vs. Ball valves: While gate valves are ideal for systems that require an on-off flow control, ball valves are better suited for systems that may require throttling. Ball valves also provide a tighter seal when closed compared to gate valves.

– Gate valves vs. Check valves: In contrast to gate valves, check valves are designed to allow the flow in one direction and to prevent flow in the opposite direction. They are not manually operated like gate valves.

– Gate valves vs. Butterfly valves: Butterfly valves have the advantage of occupying less space compared to gate valves. However, gate valves offer less fluid resistance than butterfly valves.

How to Choose the Right Gate Valve

When choosing a gate valve, you need to take several factors into account. These include:

– Material: You should consider the material based on the type of fluid the valve is going to control. For example, a stainless steel gate valve is ideal for aggressive media.

– Size: Choose a valve size that correctly corresponds to the size of the pipe in your system.

– Temperature and pressure resistance: The valve should be able to withstand the operating temperatures and pressures in your system.

To select the right valve for your application, it’s advisable to consult with a valve professional who understands your unique system needs.

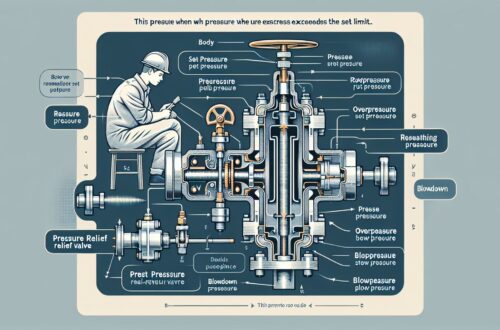

Gate Valve Maintenance and Repair

As with any mechanical device, over time, gate valves may require maintenance or repairs to remain effective⁴. This could range from replacing the packing, lapping and grinding the seats to a more comprehensive overhaul. Keeping the valve clean and free from contaminants can help increase its lifespan.

Conclusion

While there are many types of valves available, gate valves distinguish themselves due to their robustness and ability to provide secure shut-off in systems. Therefore, understanding their aspects such as their construction, working principle, advantages, disadvantages, and applications, is fundamental. If chosen, installed, and maintained correctly, gate valves can serve reliably for years to come.

References