Understanding the Basics of Ball Valves

In our daily life, we often encroach various systems and mechanisms that help in simplifying tasks. Valves are one of those limiting yet incredibly important components that we don’t realize how much we rely on. Today, we’re going to discuss an important variety of valve known as the Ball Valve.

What Are Ball Valves?

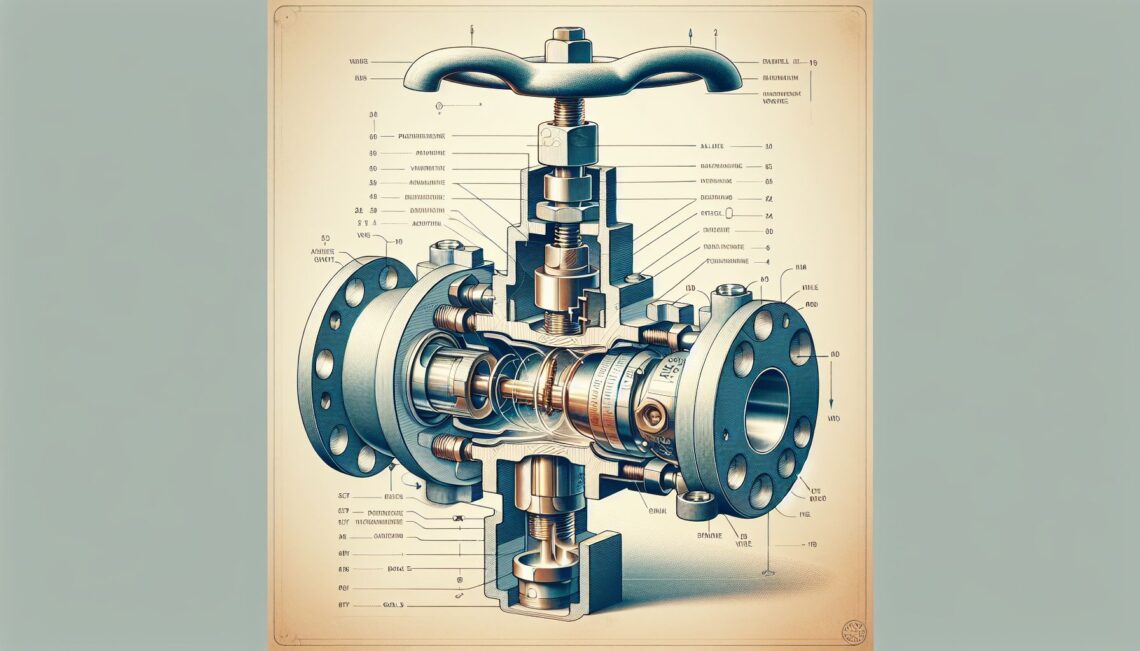

Ball valves, a type of quarter-turn valve, are quite literally named after the part of the valve responsible for controlling the flow of substances — a rotating ball. Known for being durable and providing a reliable shut-off, Ball valves are often used in both commercial and residential applications due to their durability and versatility ^1^.

Ball valves come with a port, also known as a bore. The valve opens when this bore aligns with the pipe’s flow and closes when it’s pivoted 90-degrees by the valve’s handle. The position of the handle typically offers a straightforward visual clue about the valve’s status, making it quite user-friendly ^2^.

Working Principle of Ball Valves

The ball valve operates with simplicity and ease. The ball in the valve comes with a hole or a port in the center. When the port is in alignment with both ends of the valve, the flow of the substance will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. The handle or lever will be inline with the port position letting you “see” the valve’s position ^2^.

Types of Ball Valves

Before you choose a ball valve for an application, it’s important to know that there are several types, each with its advantages and particular uses. The three most common types are:

-

Full port: They have an oversized ball so that the hole in the ball is the same size as the pipeline resulting in lower friction loss. Flow is unrestricted, but the valve is larger.

-

Reduced port: They have a smaller ball and a smaller port. The flow through the valve is one pipe size smaller than the valve’s pipe size resulting in slightly restricted flow.

-

V port: These have either a ‘v’ shaped ball or a ‘v’ shaped seat. This allows the orifice to be opened and closed in a more controlled manner with a closer to linear flow characteristic. When the valve is in the closed position and opening is commenced the small end of the ‘v’ is opened first allowing stable flow control during this stage ^3^.

Depending on your requirements, one type of ball valve may be more suitable than the others.

Applications of Ball Valves

Ball valves find their applications in a variety of areas, due to their robustness and easy operation. They are widely used in industrial applications because they are very versatile and support pressures up to 700 bar and temperatures up to 200°C. Sizes typically range from 0.5 cm to 121 cm. They are easy to repair and operate.

In addition to the typical domains, such as water, oil, and gas, ball valves are often used in the food and chemical industry. They’re also used in applications with corrosive and oxidizing elements, thanks to their full-bore design that enables an unrestricted flow of the medium ^3^.

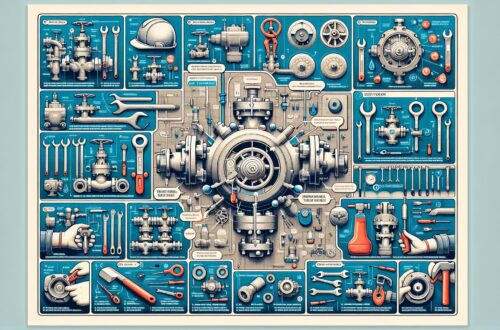

Tips for Maintenance

While Ball Valves are known for their longevity and durable design, routine maintenance is still an essential part of keeping a ball valve functional. Common elements of a maintenance routine can include regular cleaning, testing for leaks, timely replacements of broken parts, and applying lubrication whenever necessary ^1^.

Bottom Line

Ball valves, with their simplicity, longevity, and ease of use, have become an integral part of numerous industrial and residential systems. With a simple turn of a lever, they control the flow, pressure, and temperature of different gases or liquids, making many of our daily operations smoother and more efficient.