Valve Maintenance

Valves are essential components across numerous industries, providing a variety of services ranging from controlling flow rates, pressure, protecting equipment, to ensuring safe operations. However, like all equipment, they are subject to wear and tear and need regular maintenance to ensure their optimal performance and longevity. This article aims to provide a comprehensive guide on valve maintenance, covering aspects such as its importance, what it entails, and best practices.

Importance of Valve Maintenance

The importance of valve maintenance cannot be overstated. Good maintenance practices not only prolong the valve’s lifespan, but also enhance safety and efficiency[^1^]. Over time, valves may develop leaks, become harder to operate, or even fail entirely. Regular maintenance helps to identify these issues at an early stage, saving costs related to extensive repairs or replacements. Moreover, a malfunctioning valve can lead to operational hazards, making maintenance vital for ensuring workplace safety.

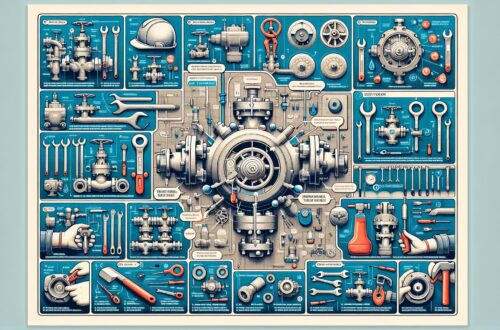

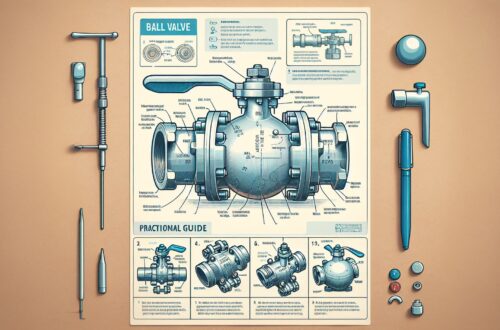

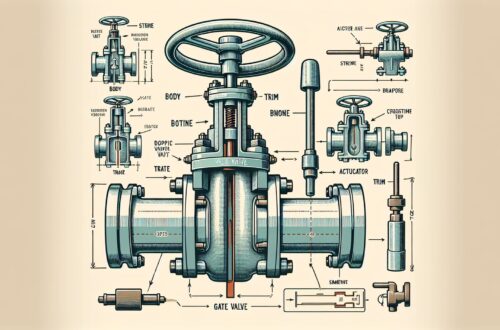

What does Valve Maintenance entail?

Valve maintenance is a broad term that encompasses a variety of tasks, including cleaning, inspection, adjustment, and repairs or replacements where necessary[^2^].

-

Cleaning: Over time, valves can accumulate dirt and grime, which impede their operation. Regular cleaning helps to maintain the valve in good condition and ensure its smooth operation.

-

Inspection: This involves checking the valve for signs of wear and tear, such as leaks, corrosion, and cracks. Inspection also involves testing the valve to ensure it operates correctly.

-

Adjustment: Some valves require regular adjustment to maintain their performance. This could involve adjusting the valve’s settings or tightening loose components.

-

Repair and Replacement: Depending on the severity of the damage, a valve may need to be repaired or entirely replaced. This typically involves disassembling the valve, replacing the faulty parts, and then reassembling it.

Valve Maintenance Best Practices

These best practices can help improve the effectiveness and efficiency of valve maintenance[^3^]:

-

Develop a Maintenance Schedule: Regular maintenance schedules should be established, ensuring that no valve is overlooked.

-

Conduct Proactive Maintenance: Proactive maintenance involves periodically checking and repairing equipment, even if no immediate problems are apparent. This approach can help prevent unexpected valve failures.

-

Train Your Maintenance Team: The maintenance team should be adequately trained in all aspects of valve maintenance. They should be able to identify the early signs of valve failure and understand how to fix them.

-

Keep Records: Record keeping is a crucial aspect of valve maintenance. It allows for tracking the history of each valve, which is useful for predicting potential future problems and developing targeted maintenance schedules.

With regular, effective maintenance, valves can provide reliable service for many years. Ultimately, the relatively small investment in time and resources that valve maintenance requires can save a considerable amount of money and trouble down the line, particularly when it comes to preventing failures and enhancing safety.

[^1^]: What is Valve Maintenance & Why is it Important?

[^2^]: Valves and their Maintenance

[^3^]: Best Practices for Industrial Valve Maintenance