Valve Maintenance: Ensuring Longevity and Efficiency

Valve maintenance is a critical task in ensuring the longevity and efficient functioning of various industrial systems. Valves play an important role in regulating flow, pressure, and temperature in many industrial applications, including water treatment, petrochemicals, and power generation. However, their functionality can be compromised by several factors such as frequent use, change in pressure or temperature, and corrosive substances. This article provides an in-depth analysis of valve maintenance practices, their importance, and the pitfalls to avoid.

Importance of Valve Maintenance

Valve maintenance offers numerous benefits to a firm’s operations. First, it prolongs the lifespan of valves, preventing premature failure. Additionally, it helps to ensure safety in industrial processes by reducing the risk of accidents caused by faulty valves. Regular valve maintenance also increases efficiency in operations, reducing downtime and repair costs.

Moreover, it aids in the early detection of potential problems, allowing for preventative measures to be put in place. Lastly, valve maintenance helps firms comply with legal safety standards, hence protecting them from potential fines and lawsuits [^1^].

Key Valve Maintenance Practices

Several practices are integral to effective valve maintenance. These include routine inspection, regular cleaning, replacing worn-out parts, and proper lubrication.

Routine inspection involves checking the overall condition of the valve and its components. Regular inspection helps in the timely detection of issues such as leaks, corrosion, and excessive wear.

Regular cleaning of valves is necessary to remove any dirt, scales or deposits that may accumulate over time. This helps to prevent blockages and maintain the smooth operation of the valve.

Replacing worn-out parts is an essential aspect of valve maintenance. Worn-out components compromise the functionality of the valve, leading to possible system failure.

Proper lubrication helps to reduce friction and wear between moving parts, thus ensuring smooth operation and prolonging the lifespan of the valve [^2^].

Pitfalls to Avoid in Valve Maintenance

While pursuing valve maintenance, several pitfalls should be avoided. Firstly, using the wrong cleaning agents or lubricants can cause harm to the valves, leading to malfunctions. It is hence necessary to consult with the manufacturer or a professional to understand the right materials to use.

Additionally, valve maintenance should not be done haphazardly; adhering to a regular maintenance schedule will ensure all valves are efficiently maintained. Using an outdated maintenance strategy or failing to adapt to changes in the industrial environment can also compromise the effectiveness of valve maintenance. Companies should continuously update their maintenance strategies to cater for any changes in technology, industry standards or legal requirements [^3^].

Lastly, proper safety measures should always be followed when carrying out valve maintenance. Failure to do so can lead to injuries or other accidents.

Conclusion

In a nutshell, regular and competent valve maintenance is non-negotiable for any firm seeking to enhance safety, efficiency, and legal compliance in its operations. By integrating a regular maintenance schedule and adapting to changes in the industry, firms can avoid costly valve malfunctions and prolong the lifespan of their valves for optimal functioning.

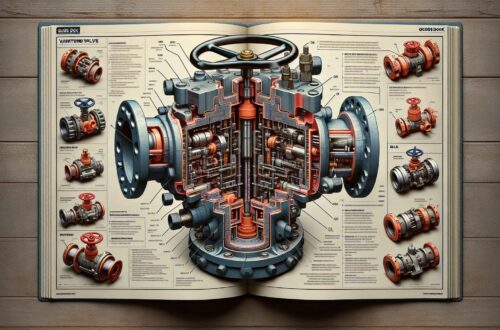

Image: Valve maintenance services (source: pixabay)

[^1^]: Industrial Valve Maintenance: Improving Safety and Efficiency