Globe Valves: A Complete Guide

In our daily life, we often interact with a plethora of mechanical components without even realizing it. Valves are strong representatives of this category, having a significant role in controlling fluid flows. Among the variety of valves that exist in the world, one of the most commonly used is the globe valve.

Today, we present a comprehensive guide to globe valves, covering their functionality, designs, materials, sizes, and applications. We’ll also delve into crucial aspects of installing, maintaining, and repairing these important pieces of machinery.

What Is a Globe Valve?

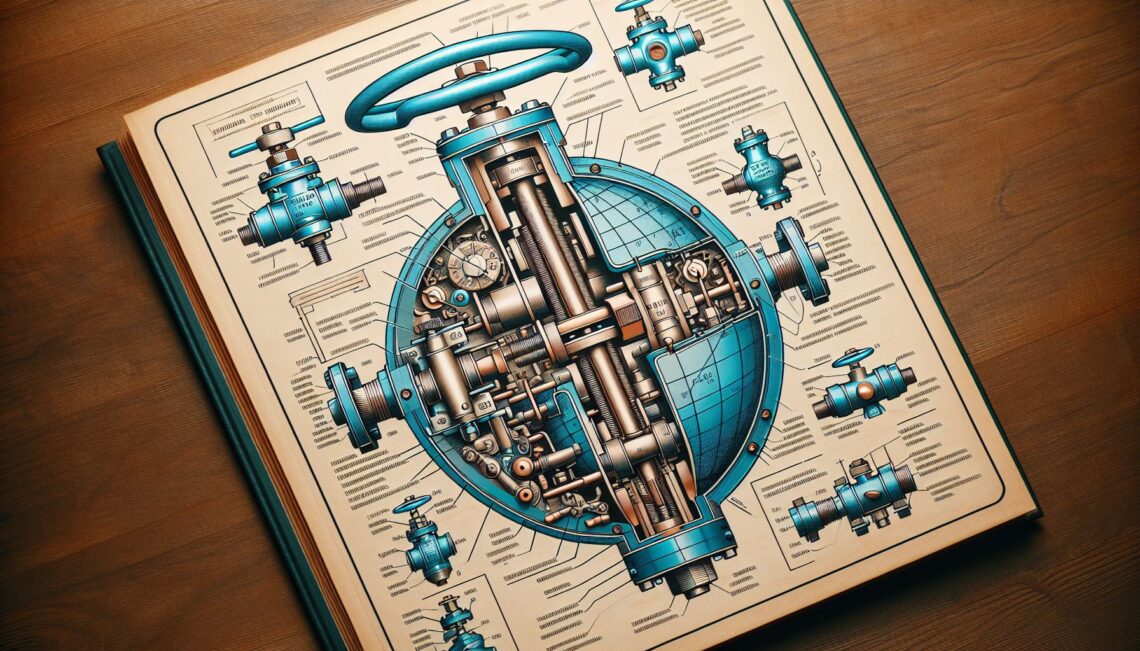

A globe valve is a mechanical device that regulates the flow of a fluid in a pipeline or duct. It works by manipulating a movable disc or plug in relation to a stationary ring seat. Flow regulation is achieved by changing the gap between the disc and the seat.

Globe valves are acclaimed for their excellent ability to control flow, but they are also efficient in circumstances where the flow needs to be completely shut off, commonly known as “valve isolation.”

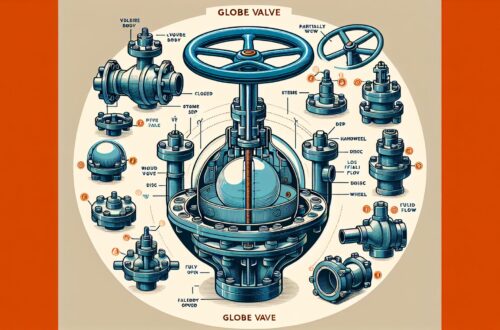

Key Components of Globe Valves

The essential elements of a globe valve include the body, bonnet, disk, stem, and handwheel. The body is a solid casing that contains all the other components. The bonnet is a cover for the body and often houses the stem, which connects the disc and the handwheel. It’s the stem’s motion that causes the disc to move and control the flow.

Globe Valve Designs and Materials

There are three prominent design forms for globe valves: Tee Pattern, Angle Pattern, and Wye Pattern. Each has its unique traits and suitable applications.

Globe valves are typically made from robust and durable materials that can resist extreme temperature and pressure situations. The most common options include carbon steel, stainless steel, alloy steel, and cast iron.

Globe Valve Sizing and Selection

When selecting a globe valve, you need to consider factors like flow control requirements, pressure drop, system pressure, fluid type, temperature, and end connections. Valve sizing is usually based on Nominal Pipe Size (NPS), which refers to the theoretical internal diameter of the pipeline where the valve will be placed.

Globe Valve Installation and Maintenance

Installing a globe valve requires preparation. Make sure you have the appropriate tools and safety equipment, and always follow the manufacturer’s instructions.

Routine maintenance of globe valves could not be more crucial. An adequately maintained valve not only operates efficiently but also prolongs its lifespan. Valve maintenance mainly involves periodical inspection and cleaning. In case of any damage, immediate repair or replacement might be needed.

Conclusion

Globe valves are indispensable components in systems that require precise flow regulation. Understanding their functionality, designs, sizing, and maintenance practices can help ensure their sufficient and efficient operation.

Sources

- Valve Manufacturing Association. “Globe Valves.” Source

- Engineering ToolBox. “Valve Types.” Source

- Valves & Fittings UK. “Globe Valves: A Complete Overview.” Source

Please note that this is a basic guide. Always refer to valve manufacturers or a professional engineer for precise information.