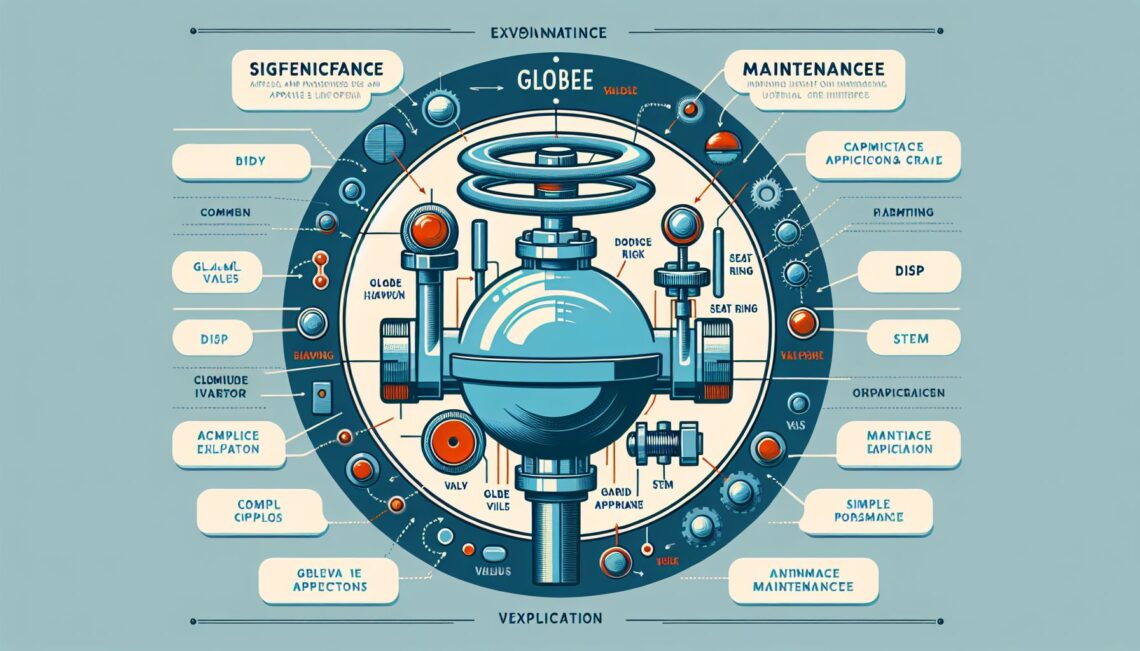

Globe Valves: Importance, Applications, and Maintenance

Globe valves play a central role in a wide range of systems related to water, oil, steam, and gas. This article aims to throw light on the critical features of globe valves, their applications, and key maintenance tips that could ensure their optimal performance over time.

Introduction

Globe valves are mechanisms that regulate the flow within a pipeline, applying a mobile disk (or plug), perpendicular to the flow, and a stationary ring seat in a broadly spherical body. They are named for their spherical bodies, which also give them unique properties compared to other types of valves.

These valves are popular for their ability to throttle flow and regulate fluid systems. This makes them very versatile and suitable for many applications that require accurate flow control[^1^].

Working of Globe Valves

A globe valve controls flow through the movement of a disk (or plug) against the flow of fluid. This disk can be entirely or partially removed from the path to control the amount of fluid that passes through. The particular design of the valve body and disk allows for precise control over the flow.

The interaction between the disc and the seat also allows the valve to act as an excellent seal when the valve is closed[^2^].

Applications of Globe Valves

Globe valves are commonly used in applications where flow needs to be adjusted regularly and also need to be shut off periodically. These include, but not limited to:

- Cooling water systems where flow needs to be regulated.

- Fuel oil system where flow control is paramount.

- Boiler feedwater and steam systems.

- Turbine lube oil system, etc.

Thanks to their design’s versatility, these valves can be effectively used in systems dealing with high-pressure drops and high temperatures.

Maintenance of Globe Valves

While globe valves are designed to be robust and reliable, like all mechanical components, they need to be maintained regularly to function properly. Here are a few tips to help ensure the smooth operation of your globe valves[^3^]:

-

Inspections – Regular checks are crucial to detect any apparent issues, such as leaks or cracks.

-

Lubrication – Ensure the moving parts of the valve, particularly the disc, are properly lubricated to prevent mechanical wear and tear.

-

Cleaning – Sediments can accumulate over time. These should be cleaned regularly to prevent blockages.

-

Parts replacement – Over time, parts of the valve may need replacement due to wear and tear. This is a usual part of maintaining any mechanical system.

-

Professional checks – While regular on-site checks are important, having a professional inspect the valve system periodically can identify and pre-empt major issues.

Conclusion

While they are a reliable and versatile choice, understanding the applications and maintenance requirements of globe valves is essential for their effective use. Regular checks, correct lubrication, and professional inspection can help ensure they continue to perform at their best for longer.

[^1^]: Globe Valve: Definition, Types, Application, and Advantages, Medium, https://medium.com/@mar_lux_22314

[^2^]: How does a globe valve work?, Bifold, https://www.bifold.co.uk

[^3^]: Valve Maintenance, Valve Magazine, http://www.valvemagazine.com