Globe Valves: A Reliable Dose of Flow Control

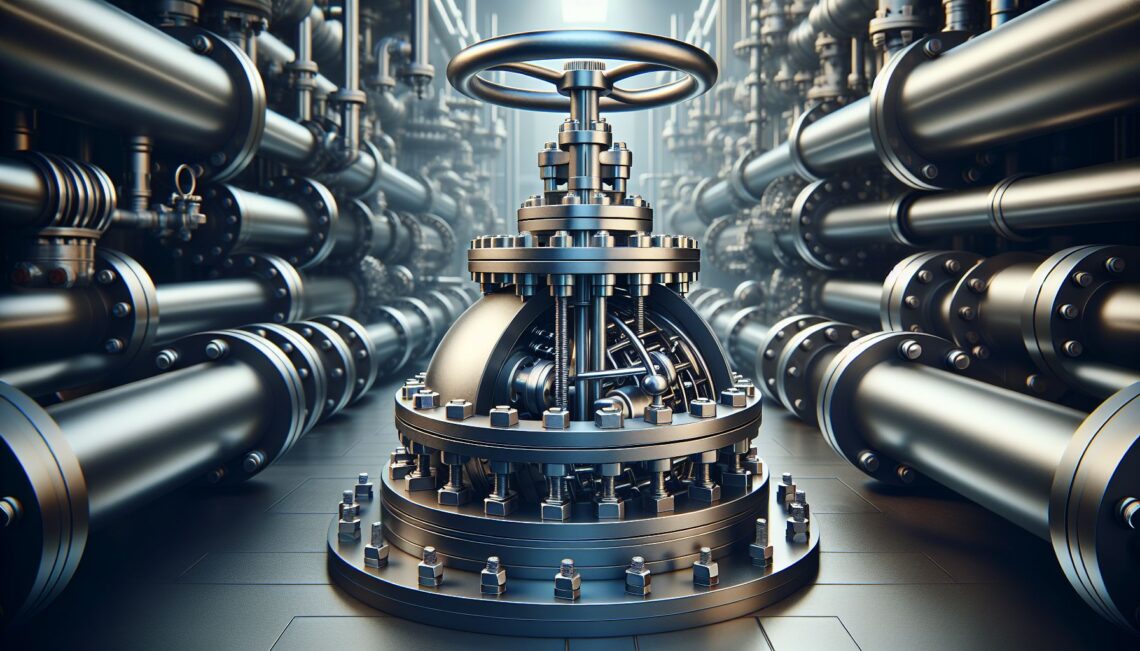

Globe valves: they may not be as glamorous as other essential tools and technologies we use every day, but they make a considerable difference in various industrial areas. These valves, packed with robust and dependable mechanisms, provide an edge in regulating fluid flow. It’s time to shine a light on this unsung hero—the globe valve.

-What are Globe Valves?

A globe valve, simply put, is a linear motion valve specially designed to stop, start, and regulate fluid flow. Its name “globe” derives from the spherical body shape that encases the valve components. It is notably versatile and can be used with everything from water and steam to oil, gas, and other corrosive materials[^1^].

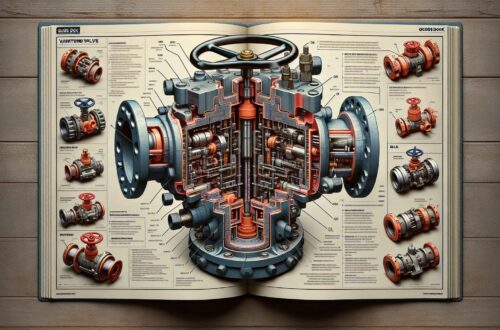

-Parts of a Globe Valve

The globe valve consists of several essential parts: the body, the bonnet, the stem, the disk, and the seat. The body holds the primary fluid area, while the bonnet is an enclosure that houses the moving parts. The stem connects to the disk or plug, regulating the clamp’s vertical movement. The disk and seat work hand in hand to start or stop the flow whenever necessary[^2^].

-Types of Globe Valves

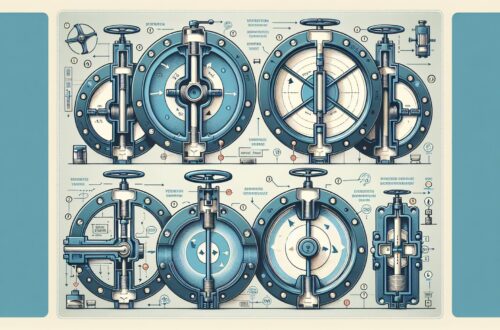

Based on their design, we can categorize globe valves into three primary types: the Tee pattern, Angle pattern, and Wye pattern. Each type holds its unique advantages and differences:

-

Tee Pattern: This is the most common type, wherein the fluid’s path has to change direction twice to pass through the valve, resulting in a high-pressure drop.

-

Angle Pattern: As the name suggests, the fluid’s path changes direction once only, reducing the pressure drop and making it a preferred choice where seamless regulation is required.

-

Wye Pattern: These valves are specifically engineered for high-pressure applications. They reduce the seating load, prolonging the valve life and improving valve efficiency[^2^].

-How Does a Globe Valve Work?

The functioning of a globe valve is fundamentally straightforward. By turning the wheel-operated stem that’s attached to the disk, you can lift or lower the disk. When fully lifted, the fluid has a clear path and thus can flow freely. Conversely, when the disk is lowered, it obstructs the flow, ceasing the fluid motion[^3^].

-Applications of Globe Valves

Globe valves are used extensively across a wide range of industries. They serve many purposes, from use in water supply pipelines, fuel oil systems, and cooling water systems to steam-boiling systems and process systems. They are particularly ideal where flow control or throttling is required[^3^].

-Advantages and Disadvantages of Globe Valves

Like all tools, globe valves come with their pros and cons.

Advantages:

- Excellent throttling capability

- Minimal leakage and damage

- Versatile with a variety of temperature and pressure conditions

- Rapid shut-off ability

Disadvantages

- May cause a significant drop in pressure

- Not suitable for slurry applications

- More expensive than other valve types[^3^].

Despite these drawbacks, the versatility and dependability of a globe valve make it invaluable in several industries. It continues to stand strong as a reliable tool for flow control, significantly contributing to our everyday life and beyond.

Hence, the globe valve serves a silent but significant role in several industrial processes we all rely on a lot.

[^1^]: Engineers Edge, Globe Valve Introduction

[^2^]: Lincoln’s Control, Globe Valve Basics

[^3^]: Valve Magazine, The Versatility of Globe Valves