Valve Maintenance: A Comprehensive Guide for Ensuring Longevity and Peak Performance

Today, we’re going to discuss an essential but often overlooked aspect of industrial operations – Valve Maintenance. In any sector, be it oil and gas, chemical, food and beverage, or utilities, valves play a significant role. They control the flow of liquids and gases in the system, affecting the system’s efficiency, safety, and reliability. Regular and proper valve maintenance is crucial to ensure the smooth running of your facility and preventing potential accidents caused by system failure.

The Importance of Valve Maintenance

Maintenance isn’t just about fixing a problem after it arises; it’s about preventing the complications in the first place. From daily inspections to periodic performance checks, proper valve maintenance can extend the life of your equipment, ensure safety, boost productivity, and save significant costs associated with equipment repair or replacement.

A Step-by-Step Guide to Valve Maintenance

Though the specifics may vary depending on the type of valve, the following is a useful general guide to maintaining industrial valves.

1. Regular Inspections

Regular valve inspections are crucial for early detection of potential issues. These checks should look for external corrosion, visible leakages, and any unusual noise or vibration during operation.

2. Lubrication

Appropriate lubrication is essential for keeping valves in top-notch condition. It can help to avoid friction between the different parts, extend lifespan, and improve performance.

3. Seal Integrity

During maintenance, the valve seals should undergo careful checks. Any sign of damage could lead to leaks and should be dealt with immediately.

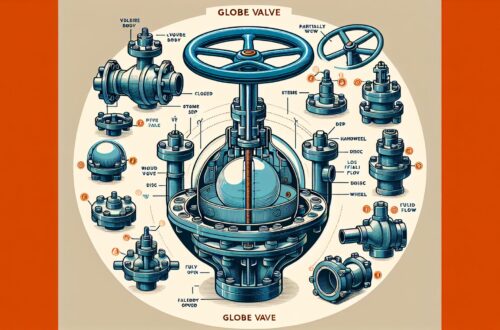

4. Internal Parts Inspection

The internal parts of the valve, including the valve seat, stem, and disc, should undergo inspection for wear or damage.

5. Calibration

The valve settings need calibration at regular intervals to ensure optimal performance. Calibration prevents under-usage or over-usage, which can both lead to severe problems if not addressed.

6. Valve Cleaning

Cleaning valves should also be part of your valve maintenance program. It’s important, particularly for those valves managing fluids prone to deposit formation or clogging.

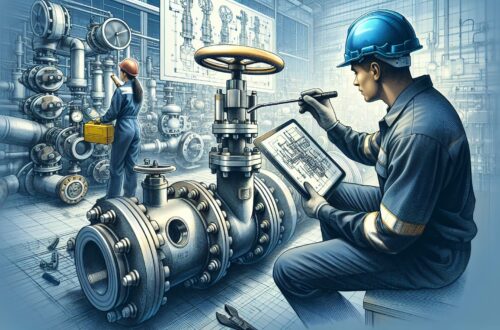

The Role of Professionals

Although some simple preventive maintenance tasks can be carried out by your site staff, not every employee is equipped with the expertise needed to efficiently maintain valves. Thus, having professionals handle the more technical aspects of valve maintenance can save you time and money.

Professional services may include machine enhancements, actuator calibration, valve disassembly, parts replacement, valve rehabilitation, and system evaluation.

When to Replace Valves?

Even with adequate maintenance, there will come a time when replacing the valve becomes inevitable. Continuous wear and tear, corrosion, or valve design limitations can lead to eventual failure. Upgrading to a higher-performance valve design or a model with better corrosion resistance might be in order in such situations.

Bottom Line

Taking the necessary steps to inspect and maintain your valves is an investment that will pay off in the long run. Whether these steps are performed in-house or by professional valve maintenance firms, the objective remains the same – to ensure your system’s reliability and efficiency.

Sources