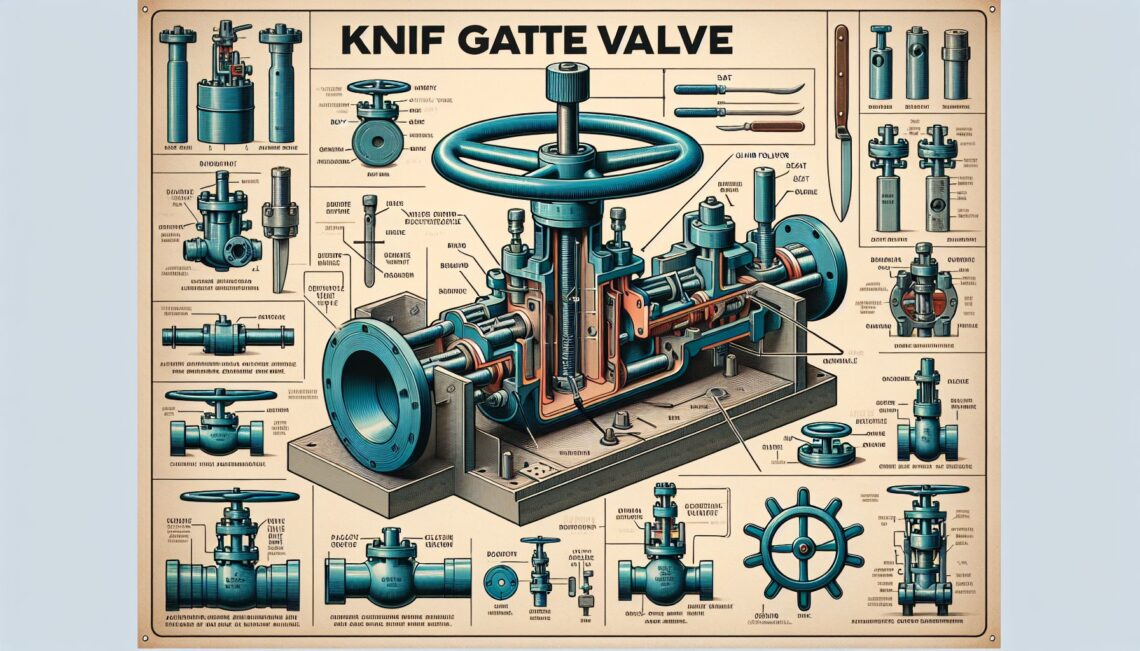

Knife Gate Valves: A Comprehensive Guide

Let’s delve deep into an essential element of industrial fluid control systems – Knife Gate Valves. These unconventional gate valves have shaped the pace of various industries such as water treatment, coal industries, and pulp and paper industries. This article aims to elaborate upon the mechanism, features, and applications of this unique type of gate valve.

Definition and Mechanism

“Knife Gate Valves”, as the name suggests, are specially designed gate valves that operate with a blade-like disk to cut through heavy liquids and slurry. Unlike the regular sliding gate valves, these come with a sharp beveled edge that enables them to penetrate viscous fluids and fiber-rich slurries, which can’t be managed by ordinary gate valves^1^.

Key Features

The primary feature of Knife Gate Valves is their thin, sharp gate that can cut through heavy liquids, solids, and slurries. This makes them perfectly suited for use in wastewater treatment plants, pulp and paper factories, food processing industries, and mining industries^2^.

In addition, their lightweight and compact design make them quite easy to install and handle. Typically, Knife Gate Valves are advertised as cost-saving options due to their relatively simple and highly efficient design.

Applications of Knife Gate Valves

As aforementioned, Knife Gate Valves find applications in various industries where the movement of heavy fluids, semi-solids, and slurries are involved.

- Wastewater Treatment: Large quantities of heavy fluids and slurries are simultaneously processed and disposed of in wastewater treatment plants. Knife Gate Valves are used to ensure a smooth flow during the process without clogging or damaging the pipelines^3^.

- Pulp and Paper Industry: Given the high-density pulp and semi-liquid materials involved in the paper manufacturing process, Knife Gate Valves are instrumental in maintaining efficient operations.

- Food and Beverage Industry: In the food and beverage industry, the valves are used to control the flow of viscous materials, like sauces and pulps in certain food processing conveyors.

- Mining Industry: They come handy in mining operations where large volumes of slurries and solid suspensions need to be handled.

Conclusion

Though not as widely recognized as other valve types, Knife Gate Valves have found their niche in industries that involve heavy-duty fluid and slurry handling. Their specialized design features and operational benefits make them indispensable for ensuring efficient and uninterrupted workflow in various industrial sectors.

Undoubtedly, the development and innovation in Knife Gate Valves will continue to match the changing needs of the industries, thereby ensuring they remain critical components in global manufacturing and processing operations.