Valve Maintenance: A Comprehensive Guide

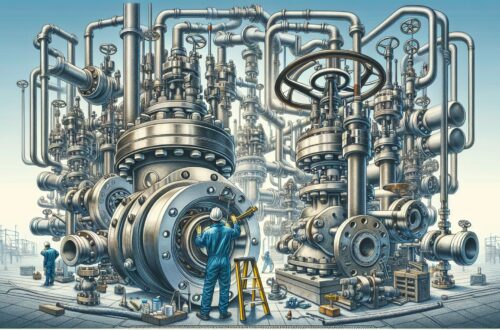

As a homeowner, plumber, maintenance engineer, or anyone involved with the management of systems that involves flow, you will inevitably come across various types of valves. Valves play a crucial role in controlling the flow mechanism in most settings, be it in plumbing systems within buildings, water supply networks, wastewater treatment plants, or industrial manufacturing sectors. Naturally, proper valve maintenance becomes a critical task to ensure the efficient functioning of all these systems. In this article, we will take a comprehensive look at valve maintenance and why it is so important.

The Importance of Valve Maintenance

Often, valves are overlooked in the maintenance schedule until there is a visible defect or system failure. This approach can lead to far-reaching and expensive consequences which could have been easily avoided with regular maintenance [^1^].

Valves, due to their role in controlling the flow of fluids and gases, are subjects to wear and tear. Over time, the accumulation of dirt, corrosion, and valve disc wear can impact the valve’s functionality leading to leaks or complete vessel shutdown. Regular valve maintenance helps in the early detection and correction of these issues and prevents any fatal system failures, ensuring smooth operation.

Key Aspects of Valve Maintenance

Cleaning

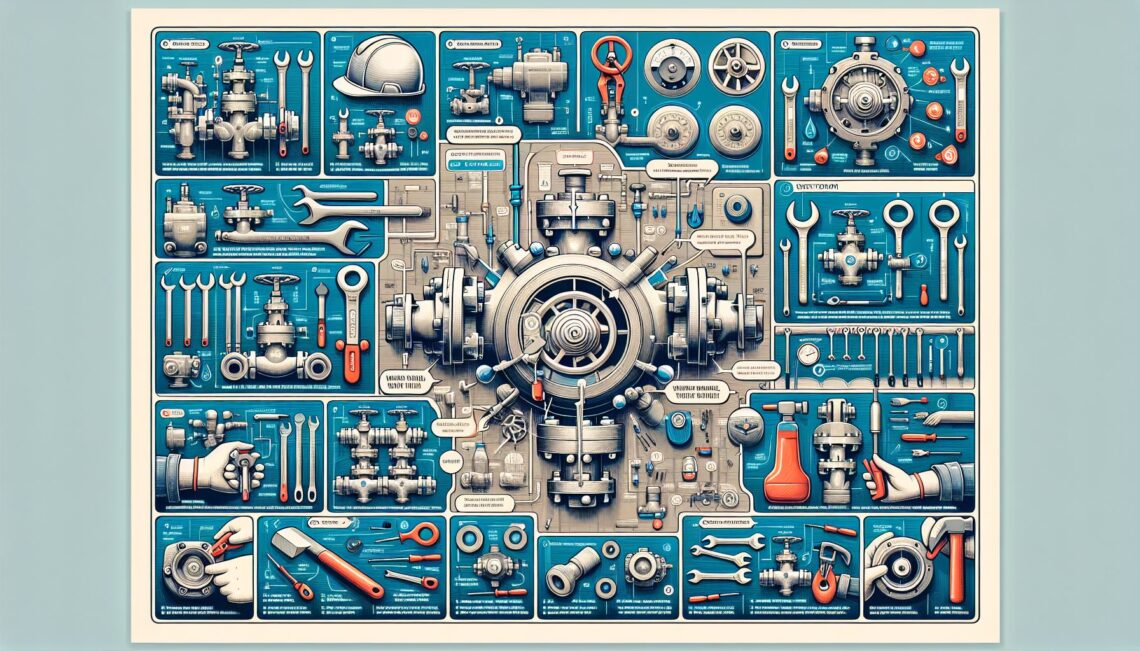

Contaminants can significantly affect the performance of the valve and lead to its failure, so regular cleaning becomes a vital part of maintenance. Cleaning methods vary depending upon the type of valve, its function, and the nature of the fluid or gas it controls. It is essential to follow manufacturer recommendations for cleaning, as wrong practices can damage the valve.

Inspecting

A regular visual check for any visible defects like leaks, corrosion, or damages further helps to assess the valve condition. Also, check for any unusual vibrations or sounds as these may indicate a defect [^2^].

Lubrication

Periodic lubrication helps to reduce friction in the moving parts, like the valve stem, thereby extending the service life of the valve. The correct type of lubricant and its right application makes a difference in valve functionality and longevity.

Testing

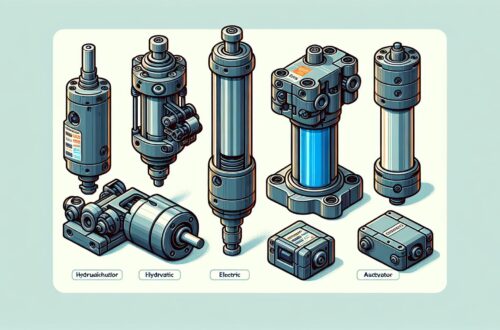

Functional checks like valve operating time, leakage tests, pressure and temperature responses, and valve actuation tests are crucial parts of the maintenance schedule. These tests help to evaluate the performance of the valve in its operating environment [^2^].

Replacement

Despite regular maintenance, valve parts can still corrode, wear out, or damage over time. Timely replacement of these components prevents further damage and ensures the valve continues to function as required.

Implementing a Valve Maintenance Plan

To ensure regular and effective valve maintenance, it is advisable to have a systematic plan in place. Identify the types of valves within the system and their respective manufacturing guidelines. Design a schedule to periodically inspect, clean, lubricate, and replace the valves as suggested by the manufacturer.

To aid in this process, modern technology offers solutions like Valve Asset Management (VAM) that provide detailed insights on the valve health, give alerts for timely maintenance, and reduce the chances of sudden valve failures.

Conclusion

While valves may be small and often overlooked components in a vast system, their role is crucial, and any lapse in their functionality can bring all operations to a halt. Therefore, valve maintenance is not a choice, but a necessity. It ensures longevity, reduces operational costs, and enhances system efficiency. Remember, a well-maintained valve equals a well-operated system.

[^1^]: Neglecting Control Valve Maintenance Can Be Costly

[^2^]: Valve Maintenance – Importance And Testing Methods